Good Quality Economical Star fire head digital inkjet textile clothing printer to Tunisia Manufacturers

Out of Stock

Good Quality Economical Star fire head digital inkjet textile clothing printer to Tunisia Manufacturers Detail:

Quick Details

- Type: Digital Printer

- Condition: New

- Plate Type: Economical Star fire head digital inkjet textile clothing printer

- Place of Origin: Zhejiang, China (Mainland)

- Brand Name: Economical Star fire head digital inkjet textile clothing printer

- Model Number: CO-1024

- Usage: Cloths Printer, All the textile fabric like Cotton, Polyester, Silk, linen etc

- Automatic Grade: Automatic

- Color & Page: Multicolor

- Voltage: 220V±10%,15A50HZ

- Gross Power: 1200W

- Dimensions(L*W*H): 3950(L)*1900(W)*1820(H)MM

- Weight: 1500KG

- Certification: CE

- After-sales Service Provided: Engineers available to service machinery overseas

- Name: Economical Star fire head digital inkjet textile clothing printer

- Ink type: acidity,reactive,disperse,coating ink all compatibility

- Print speed: 4PASS 85m2/h

- Printing Material: All the textile fabric like Cotton, Polyester, Silk, linen etc

- Print head: starfire print head

- Printing width: 1800mm

- Warranty: 12 Months

- Color: Customized Colors

- Software: Wasatch

- Application: Textile

Packaging & Delivery

| Packaging Details: | INDIVIDUAL WOODEN BOX PACKING (EXPORT STANDARD) 3950(L)*1900(W)*1820(H)MM 1500kg |

|---|---|

| Delivery Detail: | Shipped in 15 days after payment |

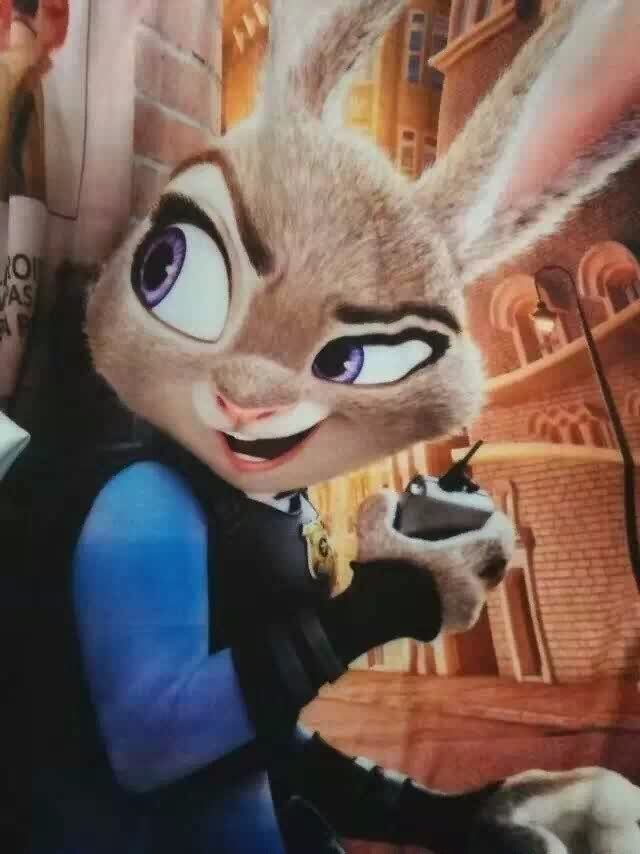

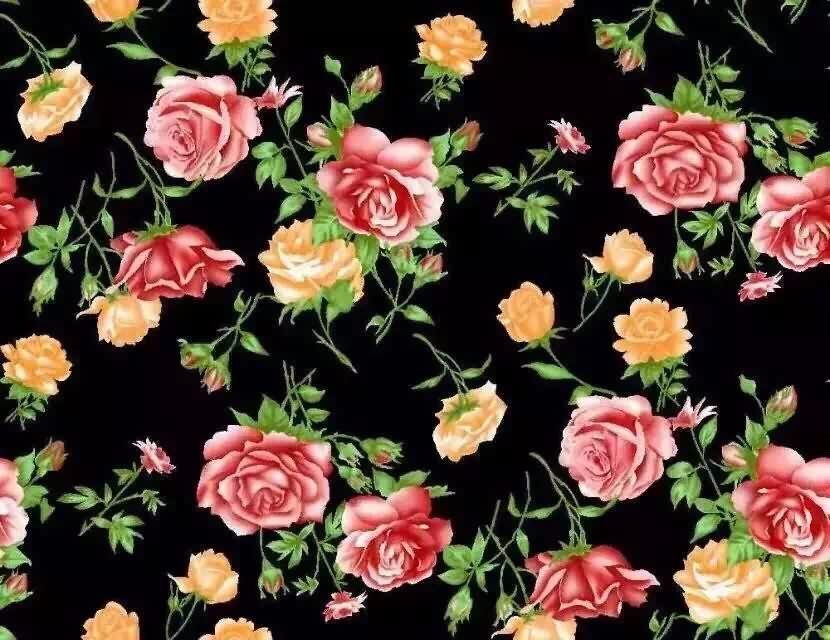

Product detail pictures:

Related Product Guide:

What Is UV Flat-Panel Printer?

Understanding the Basics of Digital Textile Printers

We retain improving upon and perfecting our items and repair. At the same time, we perform actively to do research and progress for Good Quality Economical Star fire head digital inkjet textile clothing printer to Tunisia Manufacturers , The product will supply to all over the world, such as: Bhutan, Czech republic, US, We'll supply much better products with diversified designs and expert services. We sincerely welcome friends from over the world to visit our company and cooperate with us on the basis of long-term and mutual benefits.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.