Hot Selling for Industrial 2500x1300mm UV FLATBED PRINTER with LED LAMP to Paraguay Factories

Out of Stock

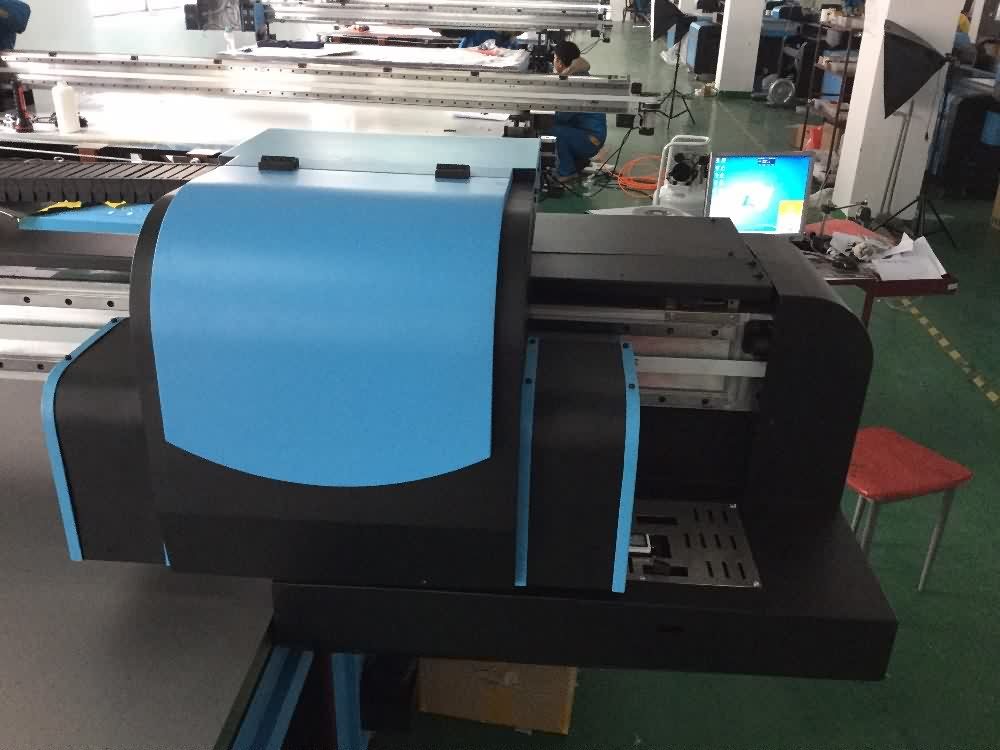

Hot Selling for Industrial 2500x1300mm UV FLATBED PRINTER with LED LAMP to Paraguay Factories Detail:

Quick Details

- Type: Digital Printer

- Condition: New

- Plate Type: Flatbed Printer

- Place of Origin: Anhui, China (Mainland)

- Brand Name: COLORIDO-A2 SIZE UV FLATBED PRINTER with LED LAMP

- Model Number: CO-UV2513

- Usage: Bill Printer, Card Printer, Label Printer, ACRYLIC,ALUMINUM,WOOD,CERAMIC, METAL,GLASS,CARD BOARD ETC

- Automatic Grade: Automatic

- Color & Page: Multicolor

- Voltage: 110~220v 50~60hz

- Gross Power: 1350w

- Dimensions(L*W*H): 4050*2100*1260mm

- Weight: 1000KG

- Certification: CE Certification

- After-sales Service Provided: Engineers available to service machinery overseas

- Name: 2500x1300mm UV FLATBED PRINTER with LED LAMP

- Ink: LED UV INK,ECO-SOLVENT INK,TEXTILE INK

- Ink system: CMYK, CMYKW

- Print speed: Max 16.5m2/hr

- Print head: EPSON DX5,DX7, Ricoh G5

- Printing Material: ACRYLIC,ALUMINUM,WOOD,CERAMIC, METAL,GLASS,CARD BOARD ETC

- Printing size: 2500*1300mm

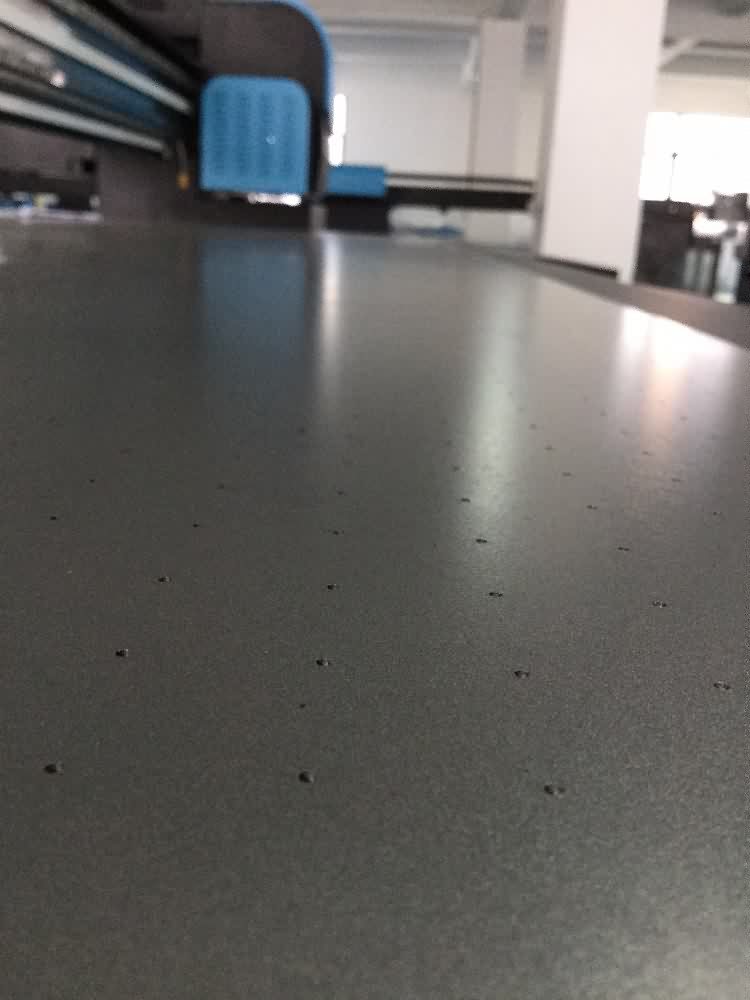

- Printing thickness: 120mm( or customize thickness)

- Printing resolution: 1440*1440dpi

- Warranty: 12 Months

Packaging & Delivery

| Packaging Details: | INDIVIDUAL WOODEN BOX PACKAGE(EXPORT STANDARD) L 1200 *W 1230* H 870 MM 350KG |

|---|---|

| Delivery Detail: | Shipped in 15 days after payment |

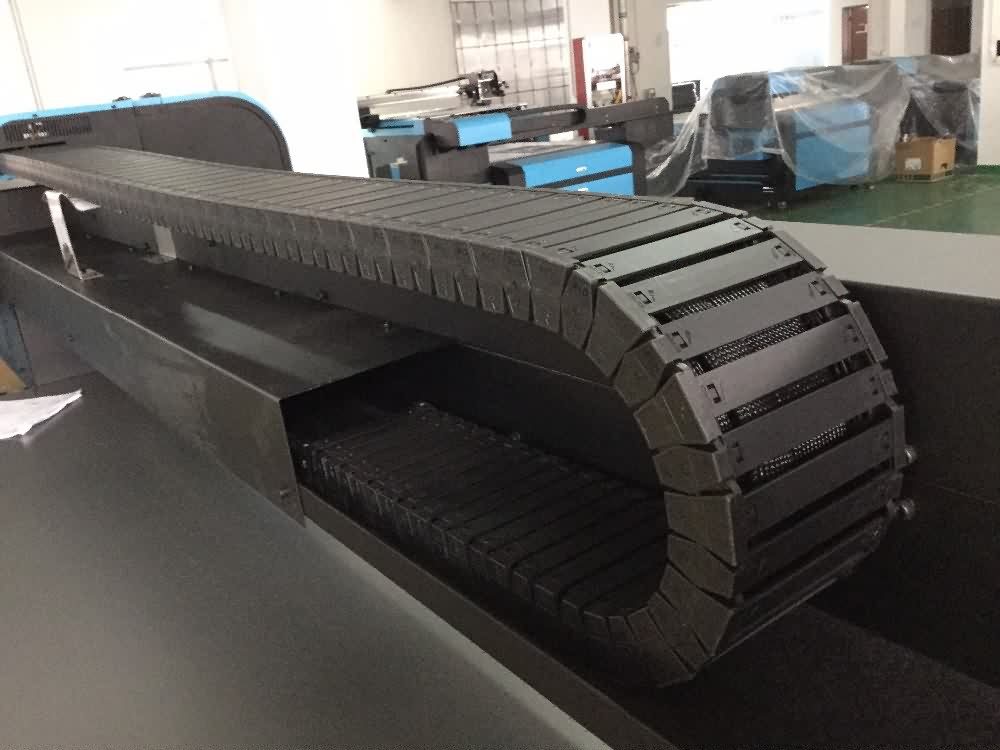

Product detail pictures:

Related Product Guide:

What Is UV Flat-Panel Printer?

Understanding the Basics of Digital Textile Printers

Dependable good quality and very good credit score standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of "quality initial, shopper supreme" for Hot Selling for Industrial 2500x1300mm UV FLATBED PRINTER with LED LAMP to Paraguay Factories , The product will supply to all over the world, such as: Romania, Malaysia, Montpellier, By integrating manufacturing with foreign trade sectors, we can provide total customer solutions by guaranteeing the delivery of right products to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified product portfolios and the control of the industry trend as well as our mature before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.