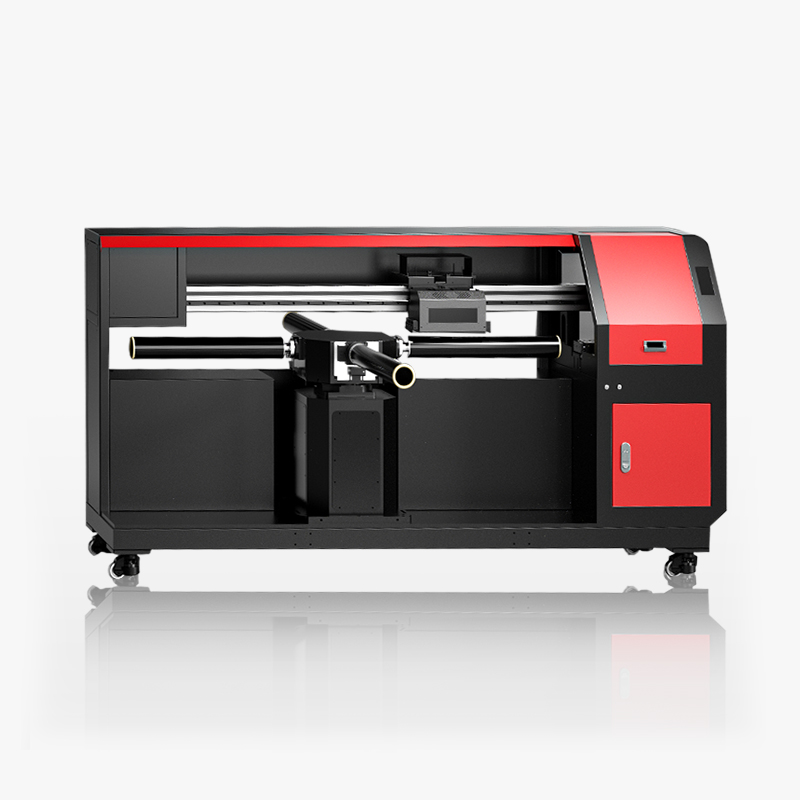

Umshini Wokuphrinta Amasokisi CO-80-210PRO

Umkhiqizi Wephrinta Yamasokisi Ochwepheshe

Iphrinta yamasokisi ye-CO-80-210Proisebenzisa imodi yokuphrinta enamarola amane, okuwumehluko omkhulu kunesizukulwane sangaphambiliniamasokisi iphrinta, okungasadingeki ukususa amarola kuphrinta yesokisi. Njengoba injini ishayela i-roller ijika ngokuzenzakalelayo iye endaweni efanele ukuze iphrinte, ayizange nje ikhulise ukunethezeka kodwa futhi ithuthukise isivinini sokunyathelisa. Ngaphandle kwalokho, isofthiwe ye-RIP iphinde ithuthukele enguqulweni yakamuva, ukunemba kombala kuye kwathuthukiswa kakhulu, ukuze kuqinisekiswe ukulungiswa okuphezulu kokuphrinta.

Izici & Izinzuzo

Isizukulwane esishaamasokisi iphrintainokuthuthukiswa okuphawulekayo kukho kokubili ihadiwe nesofthiwe. Amaphuzu alandelayo ayizinguquko eziyinhloko zalesi sizukulwane esisha sephrinta yamasokisi:

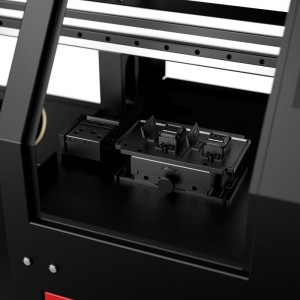

2units Of I1600 Print Heads

Iamasokisi iphrintaifakwe ama-2units wamakhanda wokuphrinta we-I1600, asekela inani elikhulu lokukhishwa komkhiqizo futhi anekhwalithi ephezulu yesithombe ku-600DPI, angaletha izithombe ezinokulungiswa okuphezulu.

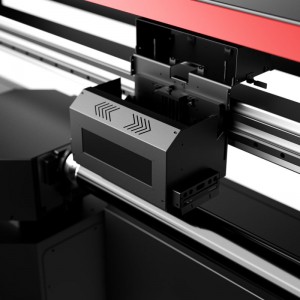

I-Cartridge Enkulu Ethuthukisiwe

Iphrinta yamasokisi edijithali ye-Colorido isebenzisa uhlelo oluqhubekayo lokuhlinzeka ngoyinki, ithuthukise amakhatriji kayinki amakhulu ukuze asetshenziswe isikhathi eside. Isistimu yokuhlinzeka ngoyinki eqhubekayo ivimbela ngempumelelo ukuvinjelwa kwe-inki kusihloko sokuphrinta futhi ivikela impilo yesevisi yesihloko sokuphrinta.

I-Four-Tube Rotation

Iphrinta yamasokisi edijithali ye-Colido isebenzisa indlela yokuphrinta enamashubhu amane ajikelezayo ukuze iphrinte. Amashubhu amane asetshenziswa ngendlela eyindilinga, ukuze umshini ube sesimweni sokusebenza esigcwele umthwalo, unamandla okukhiqiza afinyelela kumapheya angama-60-80 ngehora.

Isistimu yokulawula ye-PLC

Iphrinta yamasokisi edijithali ye-Colorido isebenzisa isistimu yokulawula ye-PLC ezimele, eyenza kube lula ukulawula umshini futhi ikuvumela ukuthi ubuke ngokuqondile isimo sokuphrinta somshini esikrinini sokubonisa.

Ukushisisa Nozzle

Inhloko yephrinta yamasokisi ithuthukiswa ngepuleti yokushisa, engaqinisekisa ukukhishwa kweyinki evamile ye-nozzle esimweni sezulu esibandayo futhi ayijwayele ukuvala.

Iphaneli yokulawula

Iphrinta yamasokisi inephaneli yokulawula ehlukile, lapho ungenza khona imisebenzi ethile, njengokuhlanza ikhanda lokuphrinta, ukuhambisa inqola, njll.

Amaphedali

Idizayini yokunyathela kabili, ungakwazi ukunyathela i-pedal lapho ulungisa amasokisi, bese uzungezisa irola ukuze ulungise ukuma kwamasokisi.

I-Industrial Square Rail

Iphrinta yamasokisi isebenzisa imigqa yesikwele yezimboni, okwenza amasokisi okuphrinta azinze futhi akhulise ukunemba kokuphrinta kwephethini.

Amapharamitha womshini

| Inombolo yemodeli./: | CO-80-210PRO |

| Isicelo sobude bemidiya: | Ubukhulu: 65cm |

| Okuphumayo Okuphezulu: | 73-92 mm |

| Uhlobo lwemidiya: | I-Poly /Cotton/Wool/Inayiloni |

| Uhlobo lukayinki: | Hlakaza, i-Acid, iyasebenza |

| Amandla kagesi: | AC110~220V 50~60HZ |

| Ubude Bokuphrinta: | 5 ~ 10mm |

| Umbala kayinki: | CMYK |

| Izicelo zokusebenza: | 20-30℃/ Ukuswakama:40-60% |

| Imodi yokuphrinta: | Ukuphrinta Kuvunguza |

| Ikhanda lokuphrinta : | I-EPSON 1600 |

| Ukulungiswa kokuphrinta: | 720*600DPI |

| Okukhiphayo kokukhiqiza: | 60-80 amapheya /H |

| Ubude Bokuphrinta: | 5-20 mm |

| Isoftware ye-RIP: | I-Neostampa |

| Isixhumi esibonakalayo: | Imbobo ye-Ethernet |

| Izindlela Zomshini.&Isisindo: | 2765*610*1465mm |

| Ubukhulu bephakheji: | 2900*735*1760mm |

Izinsizakusebenza zangemuva kokwelashwa

I-Colorido igxile ekuhlinzekeni izixazululo kumakhasimende. Okulandelayo ezinye izinto ezidingekayo ekukhiqizeni amasokisi, amahhavini amasokisi, izitimu zamasokisi, imishini yokuwasha, njll.

Isitimu sezimboni

I-steamer yezimboni yenziwe ngensimbi engagqwali futhi inamashubhu okushisa awakhelwe ngaphakathi angu-6. Yenzelwe ukwenza amasokisi kakotini futhi ikwazi ukushunqa cishe amapheya angama-45 amasokisi ngesikhathi esisodwa.

Ihhavini Yamasokisi

I-oven ye-sock yenziwe ngensimbi engagqwali futhi i-rotary, engakwazi ukomisa amasokisi ngokuqhubekayo. Ngale ndlela, i-ovini eyodwa ingasetshenziswa imishini yokunyathelisa amasokisi angu-4-5.

Uhhavini wamasokisi kakotini

Ihhavini yokomisa amasokisi kakotini yenziwe ngokuphelele ngensimbi engagqwali futhi yenzelwe ukomisa amasokisi kakotini. Ingomisa cishe amapheya angama-45 amasokisi ngesikhathi futhi kulula ukuyisebenzisa.

I-Industrial Dryer

I-dryer ithatha idivayisi yokulawula okuzenzakalelayo, futhi isikhathi silungiswa ngephaneli yokulawula ukuze iqedele ngokuzenzakalelayo yonke inqubo yokomisa.

Umshini wokuwasha wezimboni

Umshini wokuwasha wezimboni, ofanele imikhiqizo yendwangu. Ithangi elingaphakathi lenziwe ngensimbi engagqwali. Usayizi kungenziwa egcizelele ngokuvumelana nezidingo.

I-dehydrator yezimboni

I-tank yangaphakathi ye-dehydrator yezimboni yenziwe ngensimbi engagqwali futhi inesakhiwo se-pendulum enemilenze emithathu, enganciphisa ukudlidliza okubangelwa imithwalo engalingani.

Ububanzi bohlelo lokusebenza

Iphrinta yamasokisi inobubanzi obuhlukahlukene bokusebenza, hhayi okokuphrinta amasokisi kuphela, kodwa futhi ingaphrinta kweminye imikhiqizo ye-tubula elukiwe, njengamakhava emikhono, ibhande lekhanda njll. Le misebenzi eminingi yandisa imakethe engaba khona ngezimfuno ezihlukahlukene zamakhasimende.

Uchungechunge Lomlilo

Uchungechunge Lwezimbali

I-Landscape Series

I-Gradient Series

I-Cartoon Series

Izithelo Series

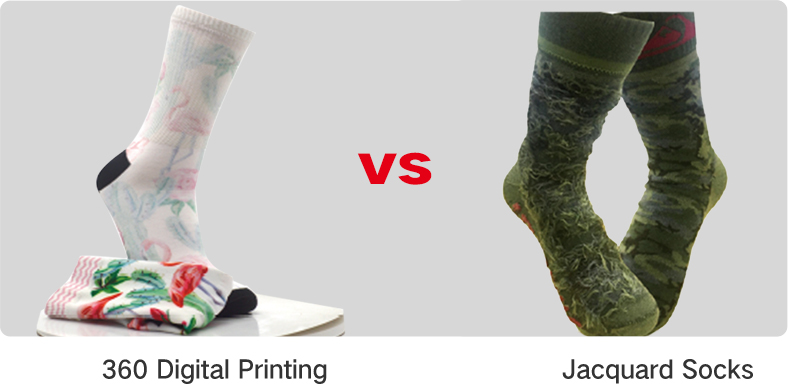

Amasokisi Okuphrinta VS Amasokisi e-Jacquard & Amasokisi e-Flat Sublimation

Amasokisi okuphrinta edijithali anezinzuzo ezinhle kakhulu uma kuqhathaniswa namasokisi ajwayelekile e-jacquard namasokisi e-sublimation. Okufana nokwenza ngokwezifiso, ukusebenza okuningi, ukuphrinta okusheshayo, imibala egqamile, ukushesha kombala okuhle, ukukhiqizwa kwemvelo nokuvumelana nezimo okuqinile.

Amasokisi Okuphrinta Kwedijithali VS Amasokisi e-Jacquard

Amasokisi ejacquard ajwayelekile ohlangothini olungemuva anemicu exege kakhulu kuyilapho amasokisi okuphrinta angenamthungo angama-360 awakaze abe nale nkinga.

Amasokisi Okuphrinta Kwedijithali VS Amasokisi Okunciphisa I-Flat

Kukhona ulayini wokuxhumana osobala wamaphethini emasokisi e-sublimationpress, kuyilapho amasokisi okuphrinta angenamthungo angama-360 angabonisa umklamo ophelele ongu-100% ngaphandle komugqa wokuxhuma.

Indlela yokwenza amasokisi e-polyester

1.Ukuphrinta

Faka ifayela le-AlP elilungile kusofthiwe yokuphrinta bese uqala ukuphrinta.

2.Ukushisisa

Faka amasokisi aphrintiwe kuhhavini ukuze uthole umbala, izinga lokushisa ku-180 C isikhathi 3-4 imizuzu.

3.Inqubo Iqediwe

Phakamisa amasokisi aphrintiwe bese uwathumela kukhasimende.Inqubo yonke yamasokisi e-polyester iphelile

Ngemva Kwesevisi Yokuthengisa

1. Nikeza ngohlelo oluphelele lwesevisi yangemuva kokuthengisa,okuhlanganisa iwaranti yesisetshenziswa, ukunakekelwa, ukulungiswa kwempahla, njll., ukuze kuqinisekiswe ukuthi amakhasimende awanazo izinkathazo phakathi nokusebenza komshini.

2. Sungula ithimba lesevisi yangemuva kokuthengisa ukuze uhlukanise futhi ubhekane nezihlukile izinkinga, ukuxazulula ngempumelelo izinkinga ezihlukahlukene, nokwandisa ulwazi lwamakhasimende.

3. Nikeza ngezinsizakalo ezibukhoma zosekelo lobuchwepheshe, phendula imibuzo yamakhasimende futhi uxhumane ngeziteshi ezahlukahlukene ezifana nekholi yevidiyo yamaqembu, ingxoxo yocingo, i-imeyili, kanye nesevisi yamakhasimende eku-inthanethi.

4. Sungula uhlelo oluphelele lokusungula izingxenye eziyisipele ukuze unikeze amakhasimende izesekeli ezidingekayo kanye nezingxenye zokulungisa kusenesikhathi ukuze kuqinisekiswe ukugcinwa okusheshayo nokusebenza kahle kwemishini.

5. Ukugcinwa njalo kwemishini kanye nokwesekwa kwesistimu yokuthuthukisa, hlinzeka ngeziqondiso zokugcinwa kwemishini nokuqeqeshwa kokusebenza nezinye izinsizakalo, ukuze amakhasimende akwazi ukuqonda kangcono futhi asebenzise kangcono imishini yokunyathelisa yamasokisi.

Umbukiso Womkhiqizo

FAQ

Umshini wokuphrinta wedijithali ongenamthungo we-360 uyisixazululo sokuphrinta se-in-one esihlomele ukuphatha inqwaba yemikhiqizo engenamthungo. Kusukela kuma-yoga leggings, ikhava yomkhono, amabhontshisi okunitha, nezikhafu ze-buff, lo mshini wokuphrinta usebenzisa ubuchwepheshe obungenamthungo ukuze ulethe ukuphrinta kwekhwalithi ephezulu, okusebenzayo. Amandla ayo anemisebenzi eminingi ahlinzeka abasebenzisi ngezinketho eziningi zokufeza imiphumela abayifunayo.

YEBO, Umshini wokuphrinta wedijithali ongu-360 ongenamthungo awunazicelo ze-MOQ, awudingi ukuthuthukiswa kwesikhunta futhi usekela ukuphrinta okudingekayo, futhi ungenziwa ngezifiso imikhiqizo.

Iphrinta yesokisi ingaphrinta noma iyiphi iphethini nokuklama ofuna ukuyiphrinta, futhi ingaphrintwa kunoma yimuphi umbala

Amasokisi aphrintiwe yiphrinta yamasokisi abeihlolweukushesha kombalafinyelelakuya ebangeni lesi-4, ayigugi futhi iyawasheka

Umshini wokuphrinta wesokisi osanda kwenziwa uklanywe kucatshangwa ngokufaneleka komsebenzisi, ovumela ukusebenza okulula kanye nesikhathi sokusetha ngokushesha. Kungakhathaliseki ukuthi ukhetha ukufunda ku-inthanethi noma ungaxhunyiwe ku-inthanethi, uhlelo lwethu olubanzi lokuqeqesha nethimba losekelo kuyatholakala ukuze kuqinisekiswe ukuzizwisa okungenazihibe. Ngezici zayo ezithuthukile namandla, le phrinta iqinisekile ukuthi izothuthukisa ukukhanga kwamasokisi akho ngenkathi ihlangabezana nazo zonke izidingo zakho zokuphrinta.

Sinikezela ngohlelo lwesevisi yangemuva kokuthengisa olubandakanya konke, oluhlanganisa isiqinisekiso segiya, ukugcinwa, ukulungiswa kokuqhekeka, njll., ukuze siqinisekise ukuthi amakhasimende asebenzisa ihadiwe ngokuthula okuphelele kwengqondo.