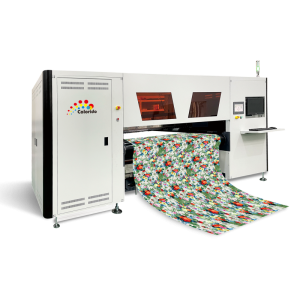

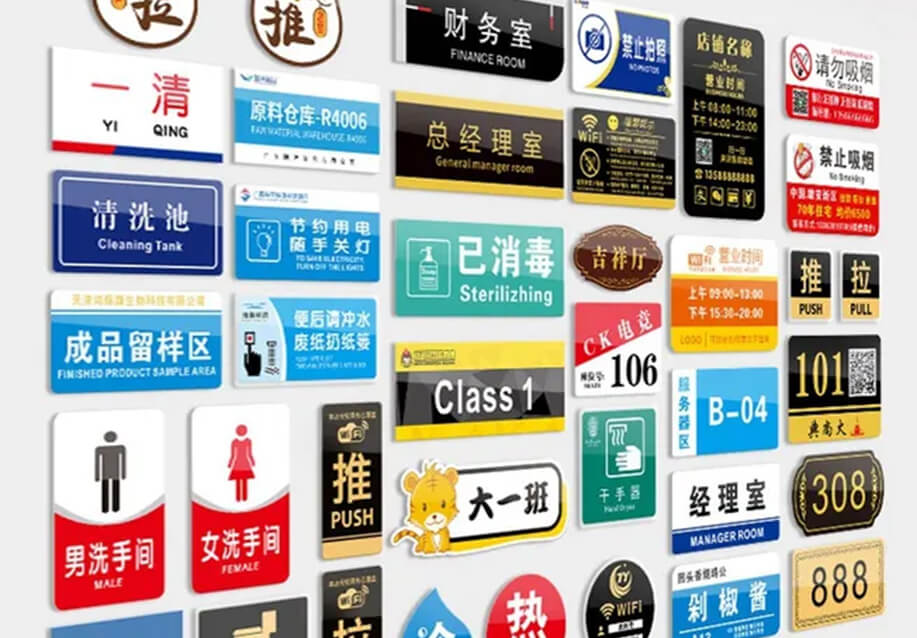

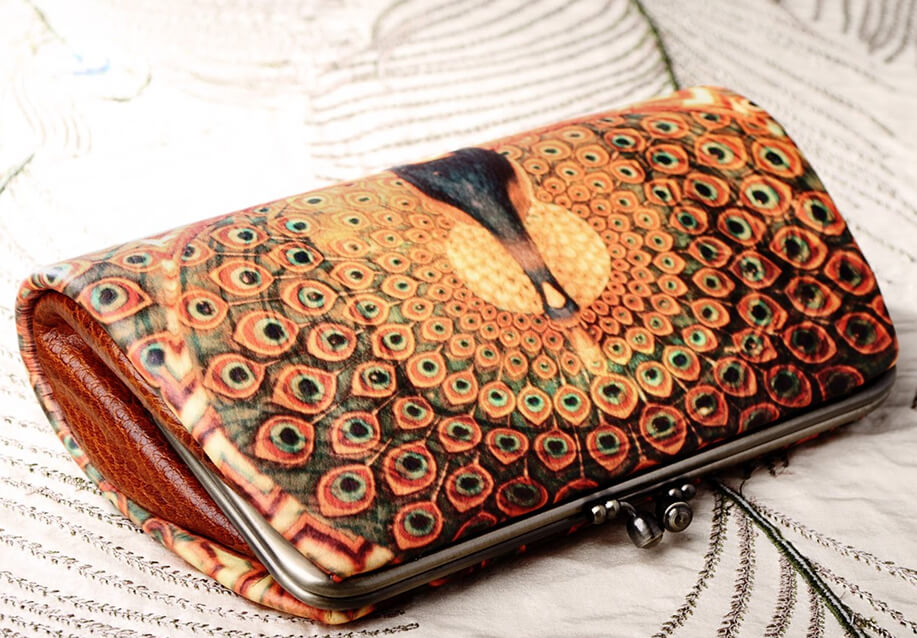

Ningbo Haishu Colorido specializes in providing customized wide-format printing solutions. Considering different product needs and market location differences, we strive the best customized solutions from planning and design till equipment installation and technical support after sale. Our product range covers a variety of digital printing equipment such as socks printing machines, dye sublimation printer, DTF printer, fabric printer, UV printer, etc., providing overall workflow solutions for brand graphics, textile and garment industries.In Ningbo Haishu Colorido, innovation and perfect service are our core direction and persistent pursuit. It has always been our consistent goal to provide lifelong equipment maintenance and high-quality assurance.

We strive for perfect compatibility between printing software and printers, find and solve problems in production process, continuously improves our digital printer.