Home Decoration Materials Printing

UV Printing Application

Master UV printing technology

print tile designs in vibrant colors.

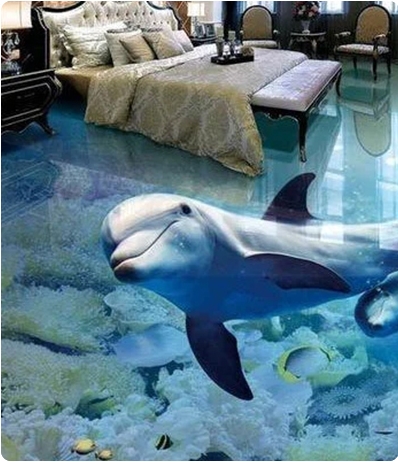

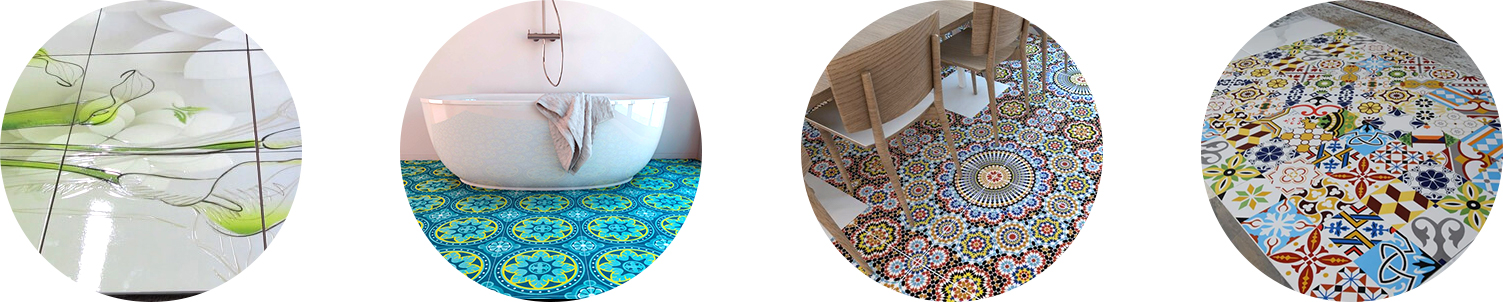

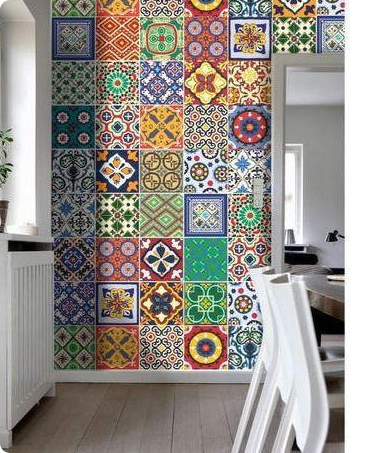

Now a days, with the advantages of magnificent colors and diversified designs, the application of UV printing technology in home decoration materials has become more and more popular in daily life. Customized and personalized products such as variety of ceramic printing and ceramic tile printing are widely accepted and used in the home furnishing industry.

Advantages of UV printing

• Quality: Tile printing solutions using UV printing technology can produce high-resolution, high-fidelity, clear graphics that can display abundant colors and details.

• Durability: The UV printer sprays ink directly on the surface of the tiles, and the ink dries immediately through UV curing system during printing. This makes the printed graphics more durable, capable of withstanding intermittent use and resistant to fading and long lasting after repeated cleanings.

• Flexible: UV printing technology can print a variety of patterns and designs, from a single image to a combination of patterns, from photos to various fonts, from simple to complex graphics, also with the white ink repeated layer printing can even achieve a concave-convex outlook and 3D effect.

• Productivity: The productivity of UV printers is very strong and efficient, the printing speed is fast, and tasks can be completed very quickly, thereby improving the production efficiency.

Application Scenario

Interior

Decoration

Commercial

Building Decoration

Kitchen

Bathroom Decoration

Art

Decoration

UV Printer-2030

• The printing area reaches 2.0×3.0 meters, which is suitable for large-area printing demands.

• Equipped with Ricoh G6 and optional Ricoh G5 print head choice, which can be selected according to the actual needs, more flexible device setting.

• The printing speed of Ricoh G6-draft mode can reach 150㎡/hour, while production mode is 75㎡/hour.

• Multi color ink options have 4 colors and 6 colors plus white, plus varnish, with the varnish on top printing, the final outlook of the graphics would be bright and long-lasting.

• It can print a variety of flat materials, such as PVC board, plastic board, metal board, and ceramic etc., and it will not fade after 5-8 years of outdoor use.

• Wide range of applications, including signage, advertising material printing, decoration material and glass, metal, gift and packaging industries are all the advantages for UV printer.

Product Parameters

| Model Type | UV2030 | |

| Nozzle configuration | Ricoh GEN6 1-8 Ricoh GEN5 1-8 | |

| Area of platform | 2000mmx3000mm 25kg | |

| Print speed | Production 40m²/h | High quality pattern26m²/h |

| Production 25m²/h | High quality pattern16m²/h | |

| Print material | Acrylic, aluminum plastic board, wood, tile, foam board, metal plate, glass, cardboard and other plane objects |

|

| Ink type | Blue, magenta, yellow, black, light blue, light red, white, light oil | |

| RIP software | PP,PF,CG,Ultraprint | |

| Power supply voltage,power | AC220v, hosts the largest 3000 w, 1500Wx2 vacuum adsorption platform |

|

| Color control | In line with international ICC standard | |

| Print resolution | 720*1200dpi,720*900dpi,720*600dpi,720*300dpi | |

| Operating environment | Temperature: 20C to 28 C humidity: 40% to 60% | |

| Machine size | 4060mmX3956mmX1450mm 1800KG | |

| Packing size | 4160mmX4056mmX1550mm 2000KG | |

Workflow For The Ceramic Tile Printing

Pattern Design: With professional design software to get suitable patterns for printing, including the text word, pictures, and other elements, to ensure that the patterns are clear and vivid to achieve the best visual effect.

Varnish Printing on Surface: Spraying the varnish on the surface of material can improve the flatness and gloss of the tile surface, thereby improving the clarity and brightness of the printing effect.

Calibrate the printer: Once finished all set up of the UV printer, then next step is the calibration as per operation manual. Including the ink type selection, install the print head and calibrating head status etc., ensure each parameter is with proper setting, and is with normal operation of the equipment.

Print collage: Input the designed pattern into the printer, and pay attention to the position of the previous one each time you print to ensure the integrity of the pattern.

Curing System: UV printer curing system utilizes the LED light to realize the curing treatment on the printed material, so that the ink can be closely combined with the surface of the ceramic material, and the color fastness and water resistance of the printed pattern can be both improved.

After-sales Service

• Sales of UV printer materials and equipment: We provide various materials and equipment required for UV printers, including ink, print head, spare parts and maintenance tools, etc. We provide high-quality products with economic price to meet customer’s demands to win the market.

• UV Printer Maintenance and Repair Services: We provide professional maintenance and repair services for UV printers, including regular inspections, maintenance and repairs, to ensure that your printers are always under the best condition. Our technical team has the experience and expertise to help you with any issue.

• UV Printer Customization Service: We provide a variety of customization services to meet up the individual needs from customers. Various UV printer-related items can be customized according to customer requirements, including custom ink formulations, special printing effects, special materials, etc. Our goal is to provide customers with the most satisfactory and high-quality customized services.

Products Display