UV Printing - Bottle Printing

UV printer now adays comes more popular for creating personalized products on a variety of materials. For example, by UV printer to print for custom bottles, it would be very essential and could reach very fast printing speeds with high-quality output. Unlike traditional printing methods that require time-consuming plate making and preparation, UV printers can directly print patterns, significantly improving production efficiency and flexibility. This technology provides a convenient and creative solution for custom production, providing unlimited possibilities for customization.

Scope Of Use

Widely application involved for UV printers like customized printing design on various materials, only request is that the surface of material needs to be smooth to ensure the adhesion and absorbency.

Advantages & Features

The advantages of using UV printers to print bottles mainly include the following aspects:

●Humanized operation: With fast printing speed, user-friendly operation and hassle-free direct printing without any drying time, UV printers provide a seamless and efficient solution for printing bottle labels.

●High-quality and vivid printing outlook: UV printing technology enables precise, vivid prints ideal for personalization purposes, with excellent quality as well.

●Multiple printing capabilities: Optimize your bottle labeling process with a UV printer, it can efficiently process a variety of bottle materials such as glass, stainless steel and plastic. UV printers are capable for printing on variety of shape of the bottles, and it is more and more involved in various industries such as cosmetics, food and beverages.

●Durable Printing: UV ink has excellent color fastness, does not fade or leave any scratch marks. It won't fade even when exposed to UV rays or chemicals. The result is durable bottle labels that retain their legibility and appeal even in harsh conditions.

●Environmental protection and safe printing: UV printing technology is eco-friendly printing process. By adopting UV printing, you can ensure safe and environmentally friendly printing practices.

Application Scenarios & Purposes

UV printers can directly display patterns, text or design drawings on the surface of the bottle, so it has a wide range of application scenarios and using purposes. Here are a few typical application scenarios and using purposes reviews:

1. Commercial marketing: UV printers can print trademarks, advertising slogans, special promotion information and other content on the bottle to increase the effect of publicity and help companies to promote and publicize their brands.

2. Holiday Celebrations: Customize holiday-themed cups, such as Christmas cups, Valentine's Day cups, etc., to help people celebrate or commemorate festivals and occasions.

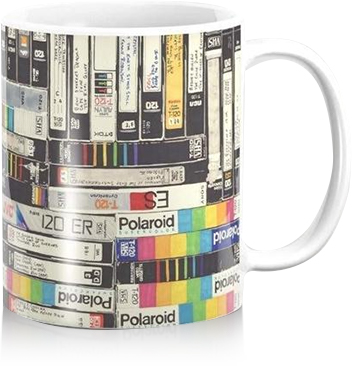

3. Personalized customization: UV printers can print out various personalized patterns, text and photos, such as personally customized cups, twin cups, etc., adding individual elements and emotional connections.

4. Gifts: Printing custom mugs allows you to add a personal touch that will make the gift feel more special and unique. You can incorporate their names, favorite quotes, or even design the mug to match their interests or hobbies. It can make a lasting impression on customers and employees alike.

5. Hotel& Restaurants: UV printers can print hotel& Restaurant brands, dishes, banquets and other information on the cups to increase consumer awareness, which is conducive to the promotion and marketing of hotels or restaurants.

6. Keepsake: Keepsake mugs can help people record special occasions or anniversaries, such as weddings, trips, etc.

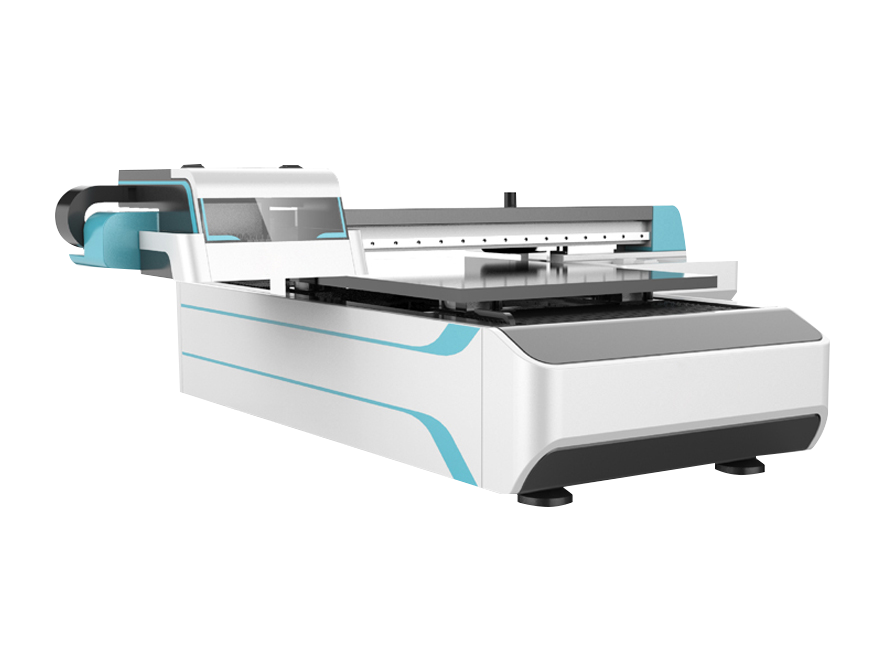

UV6090-Bottle Printing

Product Parameters

| Model Type | uv6090 |

| Nozzle configuration | epson |

| Area of platform | 600mmx900mm |

| The printing speed | Epson Three nozzles/sketch model 12m2/H/production 6-7m2/h/High quality pattern4-5m2/h |

| Print material | Type:Acrylic, aluminum plastic board, wood,tile, foam board, metal plate, glass, cardboard and other plane objects |

| Ink type | Blue, magenta, yellow, black,white, light oil |

| RIP softwar | PP,PF,CG,Ultraprint; |

| Power supply voltage,power | 110-220v 50-60hz work 1000W |

| lmage format | Tiff,JEPG,Postscript3,EPS,PDF/Etc |

| Print resolution | 720*1200dpi,720*1800dpi,720*2400dpi,720*3600dpi |

| operating environment | emperature: 20℃ to 35 ℃ humidity: 60% to 8 |

| Apply the ink | LED-UV ink, |

| The machine size | 1600mmX1500mmX700mm 280KG |

| Packing size | 1700mmX1600mmX800mm 380KG |

Workflow For Making Cups

The following is the general process of making bottle & cups by UV printer

1.Design patterns: Use Adobe Illustrator, CorelDRAW, Photoshop and other design software to make the required patterns, text and images. Convert them to formats compatible with UV printing, such as vector files, JPG, AI or PSD. Make sure the design is high resolution and fits the size of the bottle or the mug.

2.Prepare the bottle or mug: Choose a material suitable for UV printing, which can resist ultraviolet rays and has good adhesion to the ink used. Make sure the surface of the bottle/ mug is smooth, clean, and free of any contamination that could affect print quality. Clean the mug thoroughly with a suitable cleaning solution, making sure the surface is clean and free of oil.

3.Set the UV printer: calibrate the UV printer by setting parameters such as color mode, printing speed, pattern size, etc. to achieve the best printing quality. UV printers must be able to print on cylindrical and flat surfaces. Make sure the print resolution is high to produce high-quality prints.

4.Printing: Lay the bottle or cup in a fixed position on the UV printer. Load the design onto the printer using the software you used to create the design. The printer will then use a series of nozzles to spray the ink onto the surface of the bottle/ cup. UV light cure system dries the ink at the same time while printing, so once finished printing, the images would be with good colorfastness and hardly has scratching marks.

5.Finishing: After printing is complete, the bottle / cups are removed from the printer and placed in a drying station that uses ultraviolet light to speed up the drying process. The quality control process includes detailed inspection of printed products to ensure they meet customer requirements. A coat of clear varnish can be applied if desired and a final quality check is carried out before packaging and shipping to the customer.

UV Printing Market Outlook: Benefits of Bottle Printing

UV printing on bottles offers several benefits for businesses entering the custom product market:

1.Personalized needs, huge market demand potential:

Personalized needs, huge market demand potential: Driven by personalized and creative culture, customers seek unique and distinctive gifts. UV printing on bottles allows brands to personalize the experience by adding a unique logo, design or message. This resonates with customers who want to customize products to their liking, creating a huge market potential for businesses.

2.Lower production costs:

UV printing is less costly than hand-painted designs, making it ideal for mass production. Automated processes reduce time, labor and resource requirements, leading to significant savings in unit production costs. This cost-effectiveness enables businesses to price their products competitively, thereby increasing profit margins and market share.

3.Full-color high-quality printing:

UV printers use high-quality inks, which can produce clear, vivid and long-lasting printing effects. Unlike traditional methods, print quality is not dependent on design complexity. The technology enables precise, high-quality printing without plate making, reducing printing time and costs. Vibrant, full-color printing enhances the visual appeal of the bottle, making it more appealing to customers.