Application Research of

UV Printing Technology Used For Signage & Labeling

Signage & Labeling Printing

What Is UV Printing Technology?

Do you know about the UV printing technology?UV printing is a kind of high-quality, fast-drying printing technology. The printed pattern is clear, bright, waterproof and wear-resistant. Suitable for surface printing on various materials.

Application In Signage & Labeling

Packaging Label Printing

Industrial Signage Printing

Indoor And Outdoor Advertising Logo Printing

Paper Printing

Advantages

Waterproof, Moisture-Proof And Durable

UV printing technology developed curing system to cure the printed items directly after printing. This system allows the ink to dry quickly, creating a durable coating on top of the printed design. This coating is water, moisture, stain and abrasion resistant, resists contamination and moisture in different environments and makes labels more legible.

Fast Drying Speed

The UV printer adopts self-designed cooling system, combined with UV light curing technology. This system ensures that the ink cures immediately after the printing process is complete.Compared with other traditional coating technologies, the drying speed is about 0.1 second faster, which can improve production efficiency and reduce production costs.

High Precision

UV printing technology is advanced and offers high precision on variety of materials. It guarantees brilliant reproduction of images and ensures sharp lines for impeccable results.

This capability allows us to meet the precision requirements of different industries and meet the needs of our customers.

Diversity

With the multi-function of printing on variety of materials, such as metal, plastic, glass, etc., which can meet the surface treatment requirements of different materials and make the application of labels more extensive.

Environmental Protection

The implementation of UV printing technology has successfully replaced the traditional solvent-based printing methods, as well as some printing technologies with serious pollution. Advances in printing technology have significantly improved their environmental friendliness.

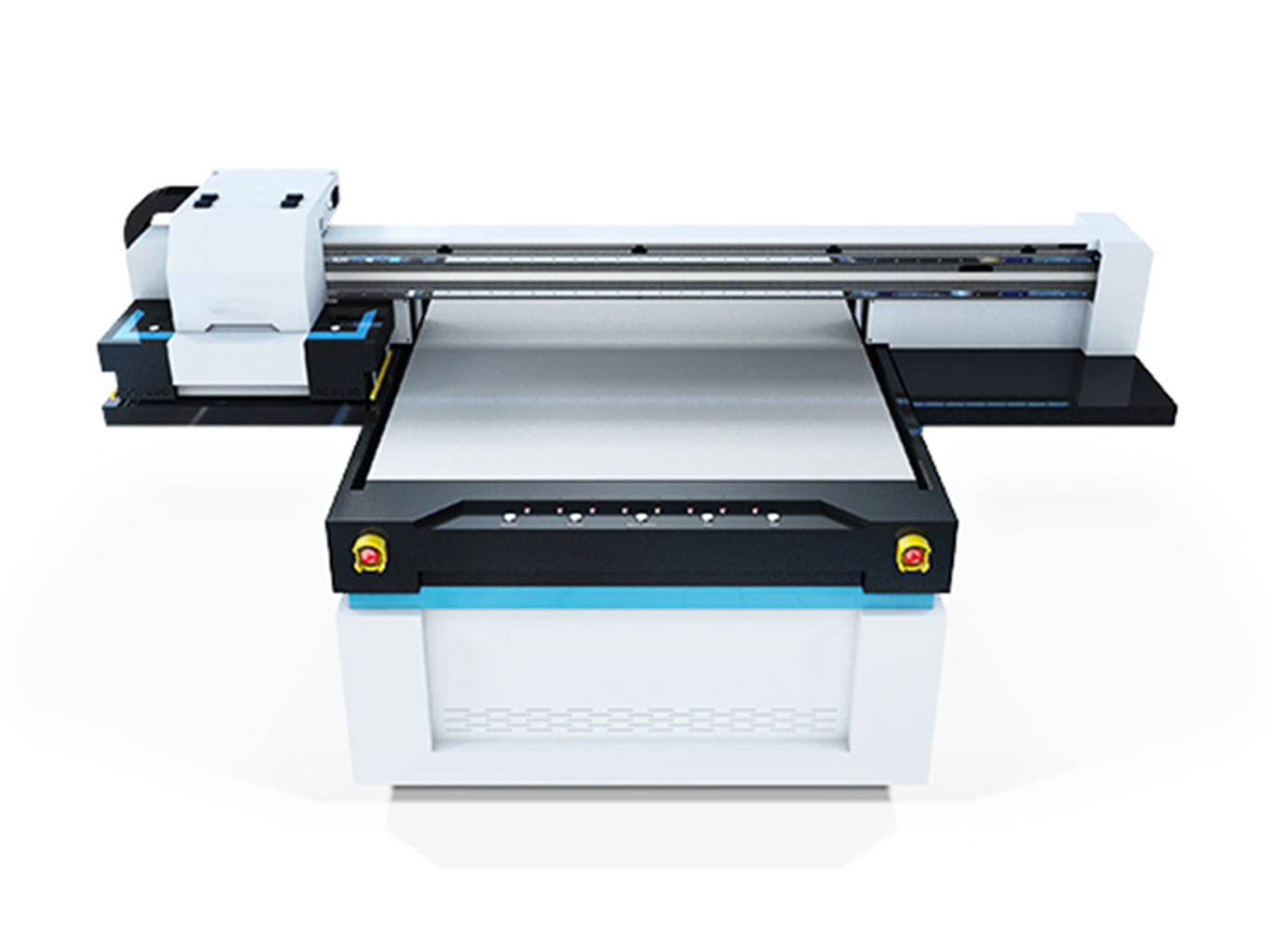

UV1313-Signage & Labeling

Product Parameters

| Model Type | uv1313 | |||

| Nozzle configuration | Ricoh GEN6 1-5 GEN5 1-5 | |||

| Area of platform | 1300mmx1300mm 25kg | |||

| Print speed | Ricoh G6 Four nozzle | sketch model 78m²/H | production 40m²/h | High quality pattern26m²/h |

| Ricoh:Four nozzles | sketch model 48m²/H | production 25m²/h | High quality pattern16m²/h | |

| Print material | Type:AcryLic, aluminum plastic board, wood, tile, foam board, metal plate, glass, cardboard and other plane objects | |||

| ink type | Blue, magenta, yellow, black, light blue, light red, white, light oil | |||

| RIP software | PP,PF,CGUltraprint; | |||

| power supply voltage,power | AC220v, hosts the largest 3000w, 1500w vacuum adsorption platform | |||

| lmage format | Tiff,JEPG,Postscript3,EPS,PDF | |||

| Color control | In line with international ICC standard,with curve and density adjustment function,using ltalian Barbieri color system for color calibration | |||

| Print resolution | 720*1200dpi,720*900dpi,720*600dpi,720*300dpi | |||

| operating environment | Temperature: 20C to 28 C humidity: 40% to 60% | |||

| Apply the ink | Ricoh and LED-UVink | |||

Signage & Labeling UV Printing Solutions

●Use high-quality UV ink to obtain more vivid colors and longer durability.

●Adopt high-resolution printing equipment to print out more delicate, clear and precise pattern text.

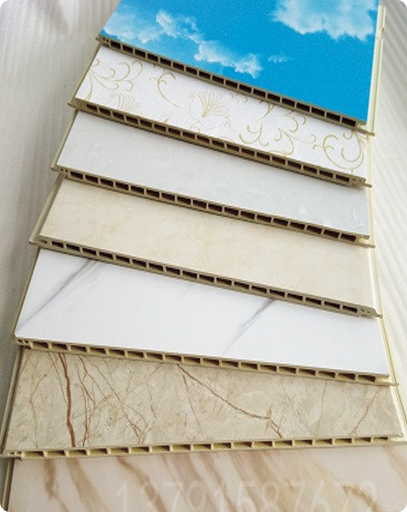

●Logo/label plates of different materials can be selected, including PVC, PET, acrylic, etc., to meet different printing needs.

●Do a good job in pre-press design, including color matching, font selection, pattern layout, etc., to ensure that the printing effect meets expectations.

●Regularly maintenance like cleaning the nozzle, replacing the filter are necessary. It can prolong the equipment using time, and also can keep the spare parts well working to improve the efficiency of printing, keep good printing quality and saving the cost as well.

●Pre-treat the surface of the product to ensure that there is no dust, oil and other ins on the surface of the product, so as not to affect the printing of the product. It is recommended to choose a special cleaning agent for cleaning.

●When designing a pattern, the details of the logo/label must be considered, such as text size, word spacing, line width, contrast, etc., to ensure the visibility and legibility of printing.

●When printing, it is recommended to check the proofs first to ensure that the printing effect meets the requirements. If you are not satisfied, please adjust in time.

●After printing, quality inspection is required to measure whether the printing effect meets the requirements. For defective products, they should be dealt with immediately to ensure product quality.

UV printing can be applied to a variety of materials, including metals, plastics, glass, ceramics, wood, and more. From rigid materials to flexible materials, whether it is flat or curved, UV printing can easily handle it.

Products Display