DTF Printer

What is DTF Printer?

DTF Printers, Print Faster & Deliver Innovation comes true

DTF printer. From the name constructure we can know that is the Direct-to-Film printer. It uses the creative digital technology to print the designs to the film directly. The film is with special coating that helps for the designs being heat transferred to the final materials later. This digital printing technology has multiple advantages such as low cost, easy operation, and transferred images with high precision and long tasting for colors.

Why Choose DTF Printer

DTF printing technology widely used in market in recent year. It comes more and more popular as a kind of new type of printing technology with the advantages of below:

High quality images

with vibrant colors

High efficiency of

production processing

Low cost for both

labor and time

Personalized design

innovation

Clothing

Hat

Bag

Cushion

Product Parameters

| Print Head Model | Epson I3200 |

| Printing Size | 600mm |

| Print Head | 2 / 4 print heads for optional |

| Color Control | Color Control |

| Printing accuracy | 1440/2160/2880dpi |

| printing speed | 16m²/H,6 Pass 25 m²/H,4 Pass |

| Powder Supply | 220V / 4500W, 50HZ/60HZ |

| temperature humidity | 15-30°C,35-65% |

| Printing Resolutions | 4 / 6 / 8 pass |

| Net Weight | 210kg |

| size and weight | machine:1885mm*750mm*1654mm,N.W180kg |

| Package:1920mm*1020mm*715mm,G.W210kg |

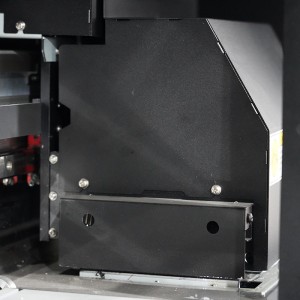

Machine Details

The DTF printer is equipped with 2 units of Epson I3200 print head, and also with the independent system of ink treatment, as well as the white ink mixing system, which ensure the printed images with vibrant color and high precision with stable operation environment during printing. Besides, the DTF printer has relative pre-drying platform which could dry the ink directly after ink, so production efficiency increased a lot.

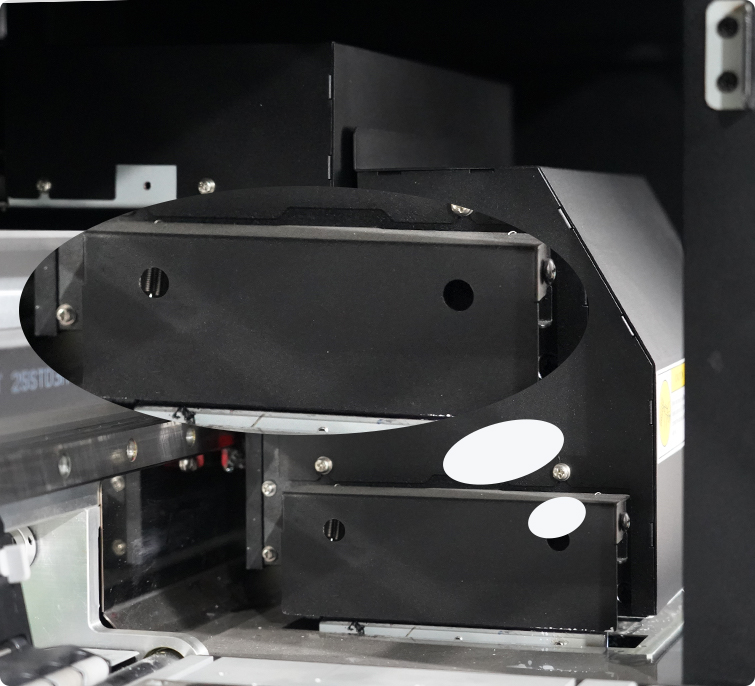

Printer Head

The DTF Printer uses Epson i3200 printheads, which could deliver either the high precision images with fast speed, or the very tiny small details involved with the vibrant images. Therefore, with Epson I3200 print head, the speed improved, the image quality is more precision and the color is more vivid, which are all the important elements for the production efficiency improving.

Pinch Roller Assemble Device

The three-wheel pressure roller device supplies the continuous and even strength for the printing material during printing, with which could achieve the stability of printing process to avoid the printing media to be shaking and skewing. Therefore, to get printing outlook high precision and accuracy.

Winding Device

One of the important parts of device for the DTF printer is the winding device, which could roll up the printed paper for formal subsequence during printing. Therefore, the printing efficiency improved greatly. It equipped with the take up tray with big durability of holding capability, very stable once it rolling up. So, this device could deliver high quality of printed image with high precision.

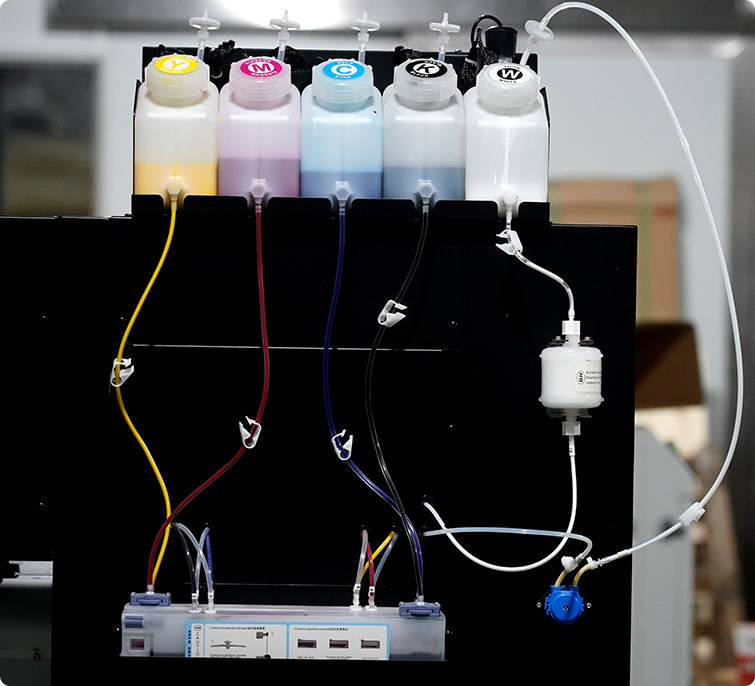

Ink System

The DTF inkjet printer adopts the continuous ink supply system, to ensure the ink would be supplied without any break during printing, therefore, to get perfect printing outlook. Besides, DTF printer also strength with the white ink stirring system which could deliver average white ink amount to be printed on the images evenly without any air bubble in the images instead.

Collision Avoidance

The DTF printer has self-protection device which could protect the print head to be anti-collision during printing process. With both sides of the anti-collision set up, print head could last long serve time and save the total cost in the end.

Secure Components

Nobody could bear the continuous noises during printing process. So, noises is also listed in the secure problem for us to pay attention to when manufacture the DTF printers. We choose high quality with ultra silent chain to low the noises as much as possible, also with good wear resistance, flexibility in disassembly and long service life for each component for the DTF printer.

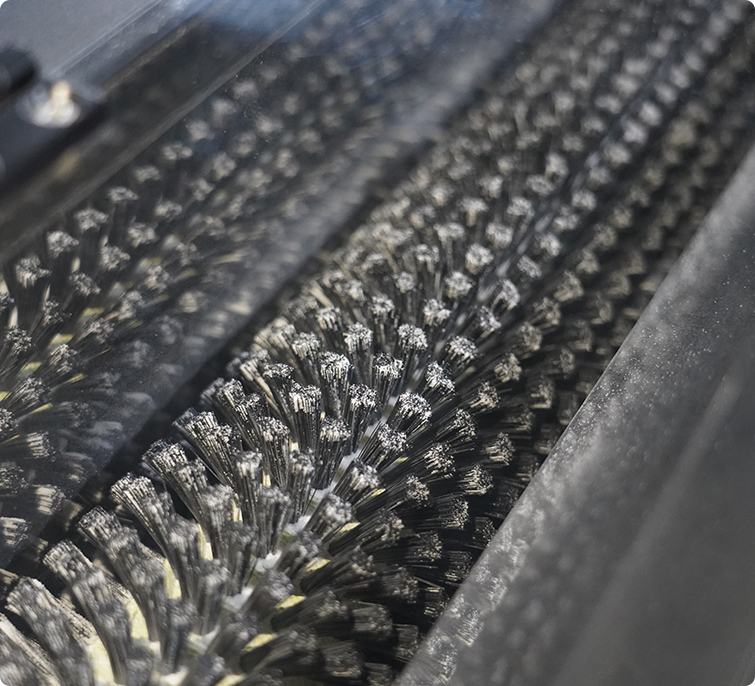

Industrial Brushing Sticks

The dusting device is an integral part of the DTF Printer, which enables uniform dusting and improves the dusting effect.

DTF Printer Printing Process

A DTF printer is the digital thermal transfer printer. By providing the special inks material and thermal transfer paper to print design images directly onto various materials. Also, with the printed images with high precision and bright color, long lasting durability, it comes more and more popular in the market, and sure, the easy operation is also one of the biggest advantages for the DTF printer. Application could be reached to the textile of apparels, home decoration, hand craft as well.

Design Approval:

Check and get design approved with size and outlook and colors with customers once get artwork fixed.

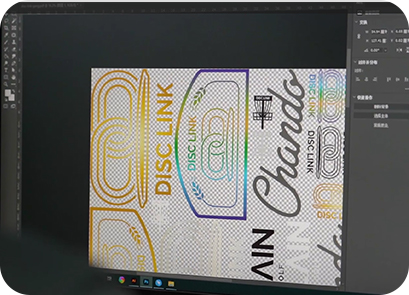

Print Pattern Management:

Use professional design software to deal with the pattern by adjustment based on client’s requirement and ensure the accurate color are full filled in the software. Then prepare the high-quality heat transfer film and ink as well to be sure the final products would be with good graphic clarity and durability.

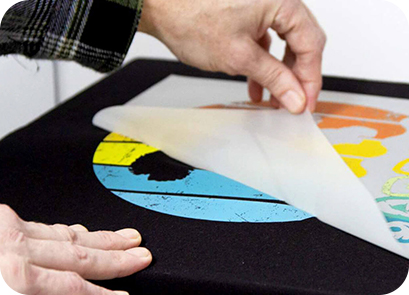

Heat Transfer:

Put the heat transfer film with proper position under the platform of the heat transfer machine, with the certain temperature with heat pressing a few seconds.

To make sure the images would be transferred from film to the final terminal material.

Cooling the Film:

Just leave the ready heating transferred products and cooling the film. Then remove the top film and then final perfect personalized products is done.

Shipment

Shipment would be completed under the full steps of inspection, testing over and over with continuously more than 3 hours printing. Ensure DTF printer would have approached good quality with everything runs well, perfect outlook of the shell with non-scratching marks on the printer. Good printing result, of course it meets the standards and customer requirements. In order to secure the equipment safety during transportation, we guarantee the sturdy wooden boxes and other security treatment would be used for packing.

Our Services

• We provide comprehensive technical support, including installation, operation skills, daily maintenance notice, etc. Our goal is to keeping proactive at the few steps ahead always! We would try our best to supply our service based on client’s concerns in front to avoid the issue happen, and try to offer resolvent before issue occurs, which try upmost best to save the down-time in zero. Once problem happened unavoidably, our technical team will respond promptly and provide clear answers and guidance.

• We also review our customers equipment in every 1 month and ensure necessary consumable spare parts would be storage in advance in clients’ warehouse.

• For the reparation lead time, we will take it as 1st priority to get it done and ensure that the equipment can be get back production smoothly as soon as possible.

• For the warranty period, we will provide free repair and replacement services in the whole service time of the equipment.

• If customers have any suggestions or comments about our products or after-sales service, it would be very appreciated to hear from you and improve ourselves to get better service.

Products Display

FAQ

The price of DTF printer has several ranges based on various supporting facilities of the machine.

Actually, it depends what model it is, then comes the method of the operation. However, generally, you would need to prepare the design or image that you want to print, load the material onto the printer, adjust the settings such as print resolution and color management, and then initiate the printing process. It is important to get familiar with the user manual and instructions for proper usage.

DTF printers have strict requirement for the ink which requested very favorite flowable ink to get better printing outlook. To buy DTF ink, you can reach out to DTF printer suppliers or authorized distributors who offer compatible ink for your specific printer model.

DTF printers have wide tolerance for the materials, including fabrics, such as cotton, polyester, and also wood, metal, glass, and even ceramics.

Trust in yourself! Nowadays just show your character and which bring you as the unique you, but not someone else. Then that design would represent you, the only you, then the design would be the suitable design. As it is mainly for the customized market with personalization designs.

It is the creative digital technology printer to print the designs to the film directly and transfer it to the different materials.