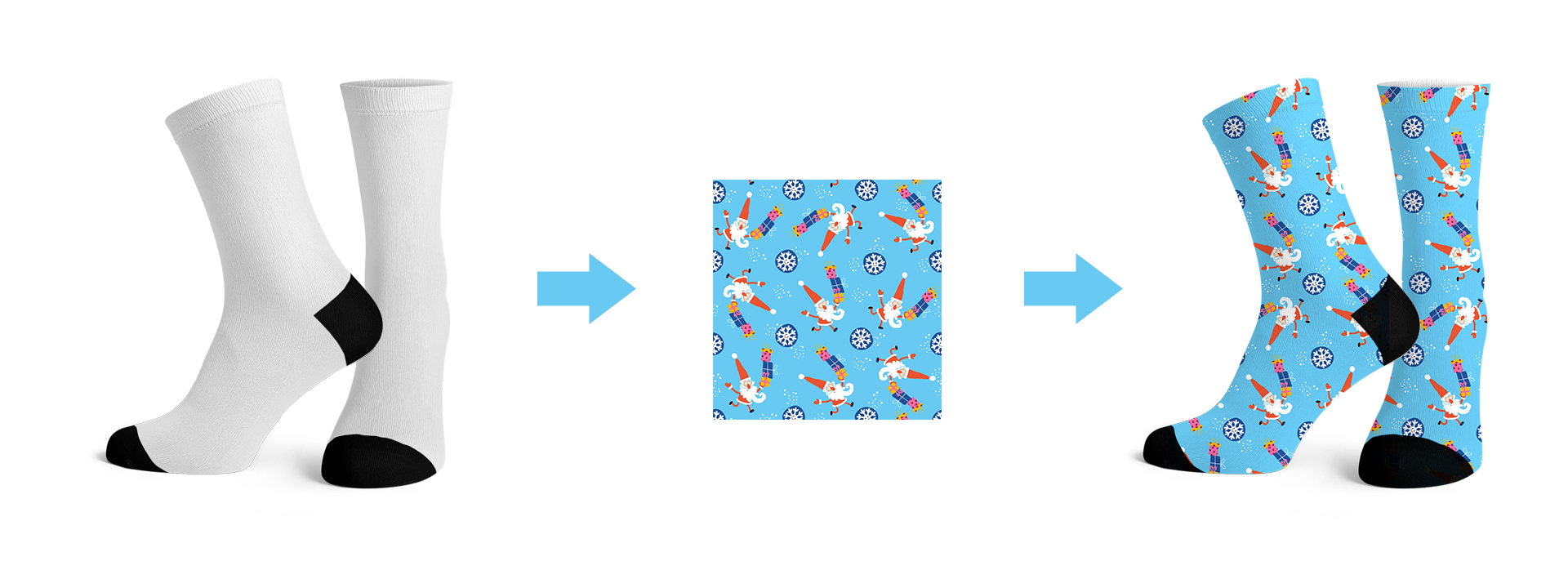

Digital printing technology is the product of the combination of digital printing and traditional printing. The socks printer uses digital direct printing technology to print the pattern on the surface of the socks. It does not require plate making and has no minimum order quantity. It has bid farewell to traditional printing. This article will introduce in detail what is a sock printer.

What is a socks printer?

The sock printer, also known as the 360 seamless digital printing machine, uses digital printing technology. The sock printer is equipped with two print heads and the latest version of RIP software. The sock printer does not require plate making, no minimum order quantity, no restrictions on patterns, and the printed patterns have no seams, supporting personalized customization.

What are 360 seamless digital printed socks?

360 seamless digital printed socks are printed by digital direct printing. The socks are placed on the roller during printing, and the ink penetrates into the yarn through the printing to color the socks. There are no extra threads inside the digital printed socks, and they will not show white when stretched. The patterns of the printed socks are bright and colorful, and there are no restrictions on the colors and patterns. The color fastness reaches level 4-4.5.

What are the advantages of 360 seamless digital printed socks?

No minimum order quantity: You can print with a sock printer without a minimum order quantity.

High production volume: The sock printer uses the latest digital printing technology to produce 50-80 pairs of socks per hour.

Personalization: Customers can customize it according to their needs and make a unique gift during holidays or special occasions.

Production Flexibility:Using sock printer can realize small single quick response, and adjust according to market demand.

Colorful:Computer color matching is more accurate, CMYK/RGB mode has a wider color gamut, and the micro-spray effect makes the printing details clearer and the color transition more delicate.

Conclusion

The emergence of 360 digital printing socks breaks the barriers of traditional printing socks. Its production capacity is greater, more environmentally friendly, and energy consumption costs continue to decline. Digital printing technology is the trend of future development, fast fashion, and fast response.

Post time: Jun-05-2024