12 Years Manufacturer Sublimation paper for sublimation ink printing to Iraq Importers

Out of Stock

12 Years Manufacturer Sublimation paper for sublimation ink printing to Iraq Importers Detail:

Quick Details

- Material Type: Paper

- Material: White Paper

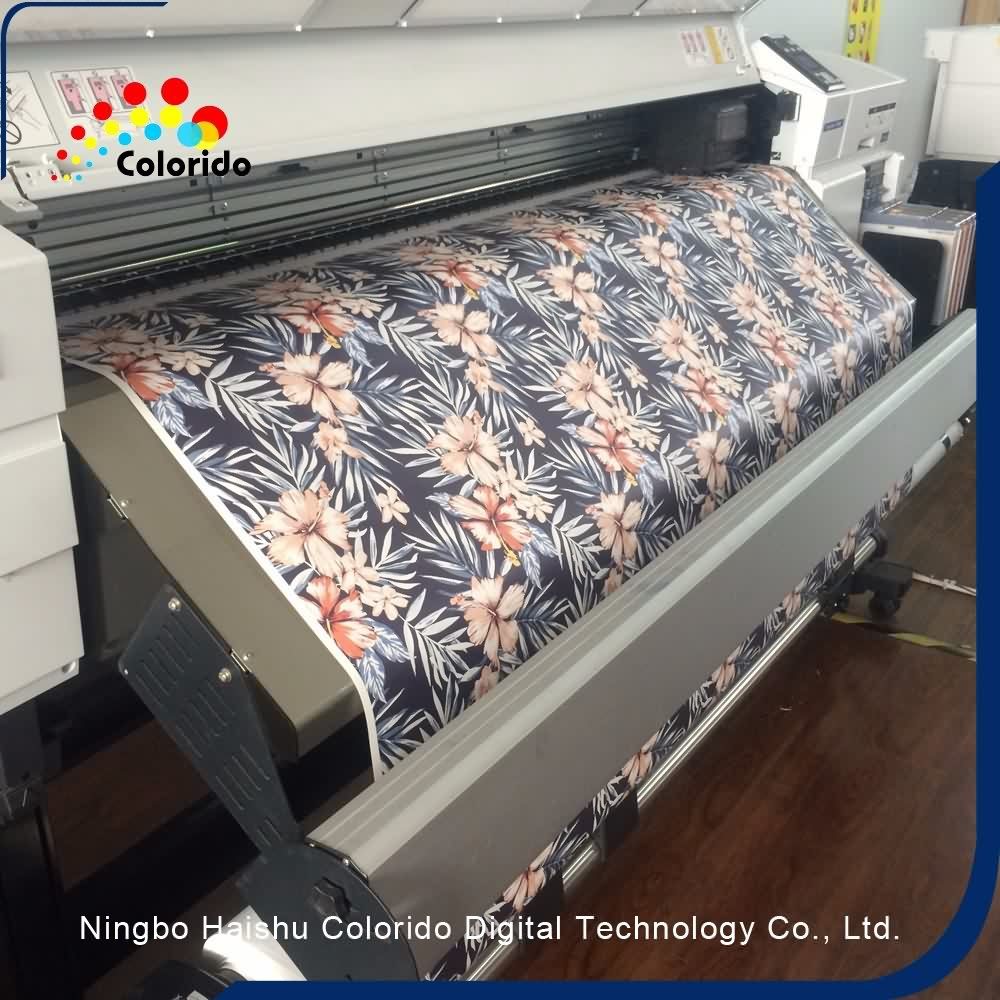

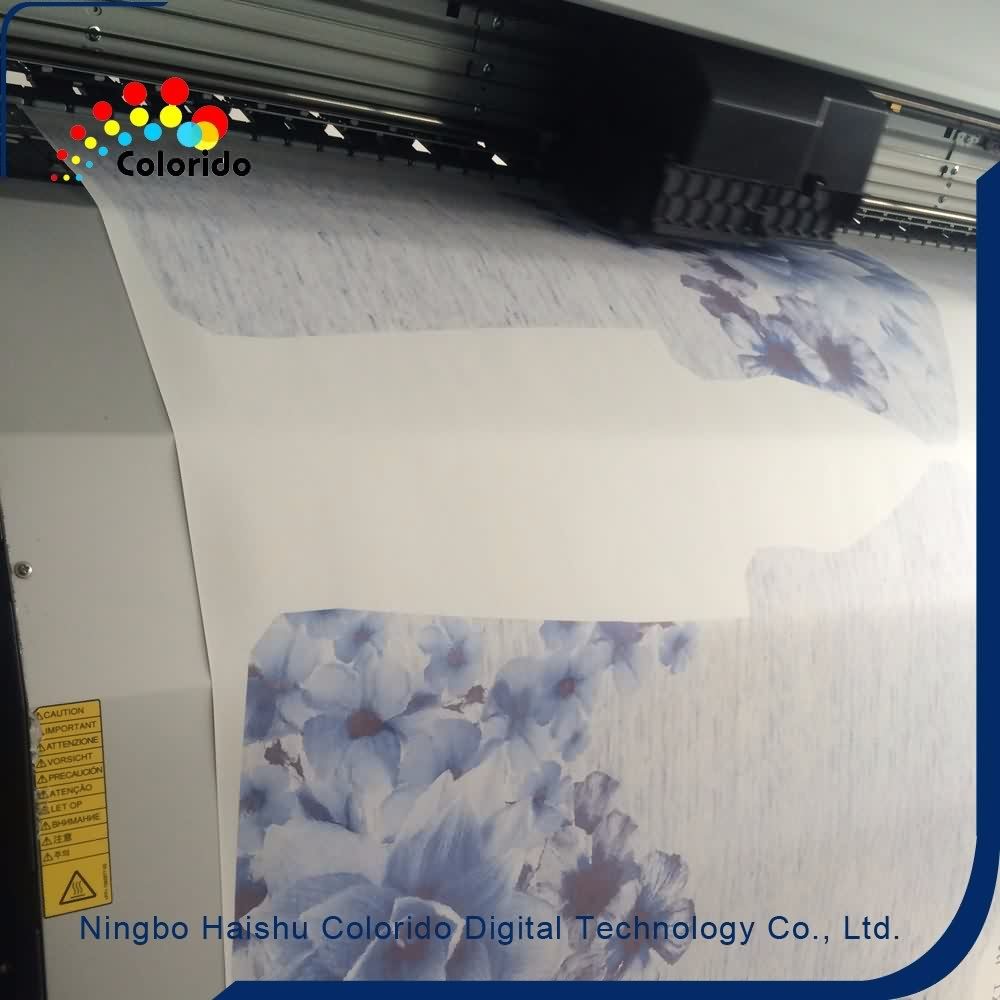

- Application: Textiles

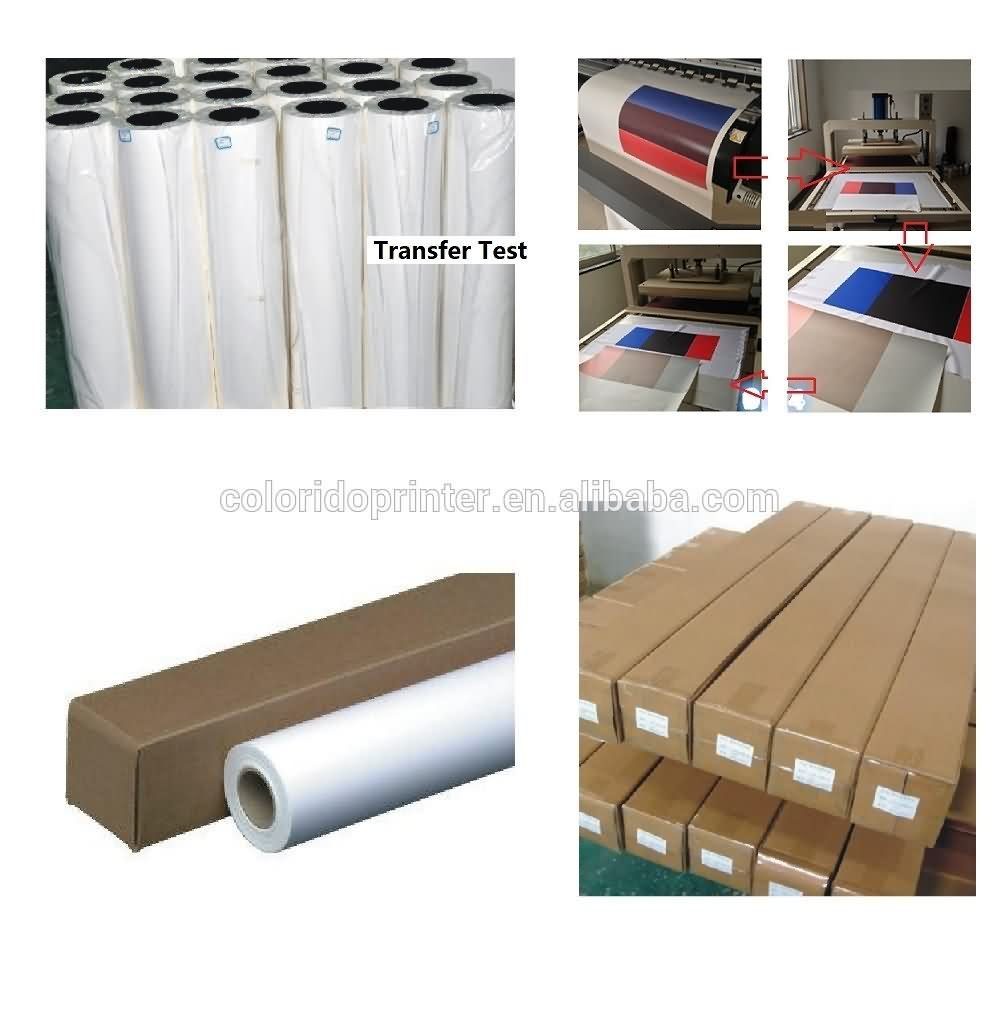

- Type: Sublimation Transfer

- Place of Origin: Zhejiang, China (Mainland)

- Brand Name: OEM

- Model Number: DYE-100

- Product name: Sublimation Paper

- Regular Size: 0.61/0.914/1.118/1.6/1.9*100M

- Ink: Water Based Sublimation Ink

- Gram weight: 70g(80/90/100/110/120g also available)

- Color: Pure White

- Quality: A

- Transfer rate: 95%- 98%

- Drying time: 30s

- Delivery time: 3-5 Working Days

- Packing: OEM

Packaging & Delivery

| Packaging Details: | exported standard package |

|---|---|

| Delivery Detail: | 3-7days |

Product detail pictures:

Related Product Guide:

What Is UV Flat-Panel Printer?

Do You Know the Printing in China?

Our focus on should be to consolidate and enhance the quality and repair of present products, in the meantime constantly establish new products to meet unique customers' requires for 12 Years Manufacturer Sublimation paper for sublimation ink printing to Iraq Importers , The product will supply to all over the world, such as: Comoros, Chicago, Brunei, Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our products and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!