Factory For Dye Sublimation Printer 15Heads CO51915E to Albania Factories

Out of Stock

Factory For Dye Sublimation Printer 15Heads CO51915E to Albania Factories Detail:

Dye Sublimation Printer

15 Heads CO51915E

Dye Sublimation Printer CO51915E uses 15 Epson I3200-A1 print heads, with the fastest printing speed of 1pass 610m²/h. With its fast printing speed, it can provide printing on a variety of materials. On-demand printing is very popular in the market.

What materials can be used for dye sublimation printing?

Dye-sublimation uses dispersed ink and can be transferred on polyester, denim, canvas, blended and other materials. Not only that, it can be transferred on some ceramics, coffee cups, and thermos cups.

Flag Printing | Sports Apparel | Fabric | Decor | Signage | Custom Products

Product Parameters

| COLORIDO CO51915E Sublimation Printer | |

| Printhead:Epson 13200-A1 | Nozzle Quantity:3200 |

| Printhead Quantity:15 | Print Width:2600mm |

| Print Colors:CMYK/CMYK+4 COLORS | Print Height:2-5mm |

| Max.resolution(DPI):3200DP | Media Transmit:Auto Taking-up Meida Device |

| Max speed CMYK(1.9m printing width, 5% feather):1pass 610m²/h | Drying Method:Extra Dryer Device |

| Ink Supply Method:Siphon Positive Pressure Ink Supply | Head MoistureMethod:Auto Head Cleaning and Moisturizing |

| Print Media:Transfer Paper | Bulk Tank Capacity:5L |

| Material Transmit:Dual Motors System | Ink Type:Sublimation InkWater Based Pigment Ink |

| Transmission Interface:Gigabit LAN | Max. Media Taking up (40g paper):1500M |

| Max. Media Feeding(40g paper):2000M | Computer System:Win7 64 Bit / Win10 64 Bit |

| File Forms:TIFF,JPG, EPS,PDF, etc. | Operate Environment:Temp.: 15°C-30°CHumidity:35°C-65°C |

| RIP Software:Printfactory, Maintop, Flexiprint, Onyx, Neostampa | Printer Size:3900*1340*1980mm |

| GW(KGS):1500 | Package Size:3900*1540*2000mm |

| Power Supply:210-230V50/60HZ,16A | Dryer Power: Max.9000W |

| Print Power: 1500W | |

| Computer Configuration:Hard Disk: NTFS, C Disk Space: More than 100G, HARD Disk: WG500G GPU: ATI Discrete GPUMemory: 4G, CPU: Intel 15/17, G-Ethernet | |

| Standard Configuration | Ink Level Alarm System |

Detailed Display Of Sublimation Printer

The following are some details about sublimation printers

Ink Tank

Upgraded Ink Tank, using 5L large-capacity ink cartridges with built-in ink shortage alarm to ensure longer printing. The continuous ink supply system improves production efficiency and avoids plugging during the production process.

Adsorption Platform

CO51915E dye-sublimation printer uses an aluminum alloy adsorption platform with a smoother surface. This prevents the paper from wrinkling during the printing process and improves printing accuracy.

Ink Chain

The function of Ink Chain is to protect ink circuits, wires, and optical fiber lines from wear and tear after long-term use.

Notes

• This product only uses original COLORIDO ink. We are not responsible if other incompatible inks are used to damage the nozzle.

• The printing speed of the printer depends on the selected PASS number. The higher the precision, the slower the printing speed.

• Consumable materials such as nozzles are not covered by the warranty.

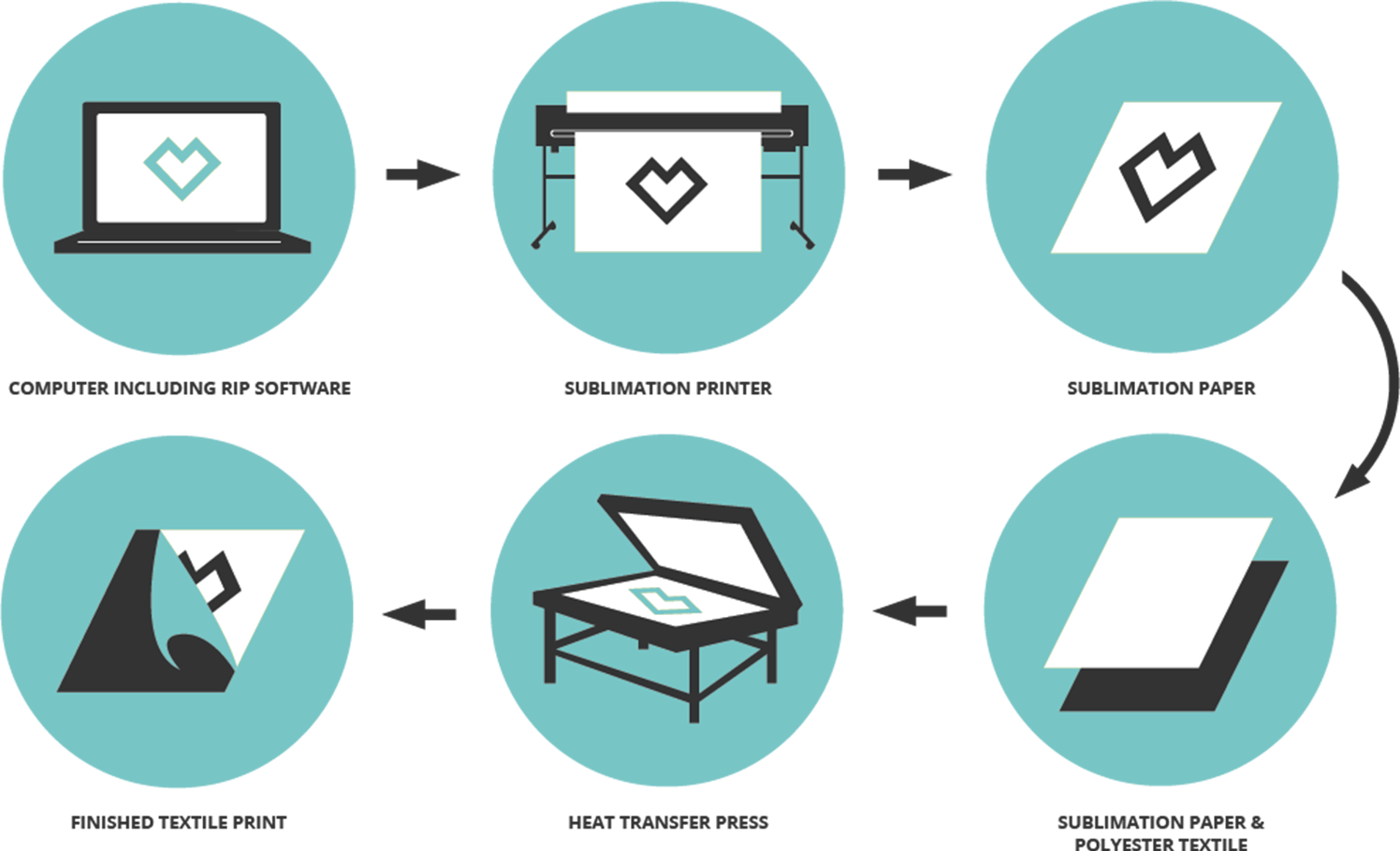

Dye Sublimation Printing Process

Dye Sublimation Printer is easy to operate. The following is the operation process of the dye sublimation printer.

FAQ

1. How much does a dye sublimation printer cost?

Dye-sublimation printers, starting at less than $10,000. Also, you will need additional equipment such as a heat press or cutting machine

2. How long will a dye sublimation printer last?

Under normal use, the life of the printer is 8-10 years. The better the maintenance, the longer the life of the printer.

3. How long with my dye sublimated item last?

The adsorption capacity of inks of different materials also varies. Since the sublimation process involves the inks being chemically bonded to a material, decorated items permanent and washable.

4. How will I know how long an item should be sublimated for? And what temperature should the printer be?

Printing time and temperature depend on the material being printed. Generally, the following times and temperatures are recommended:

For polyester fabrics – 400F 40 seconds

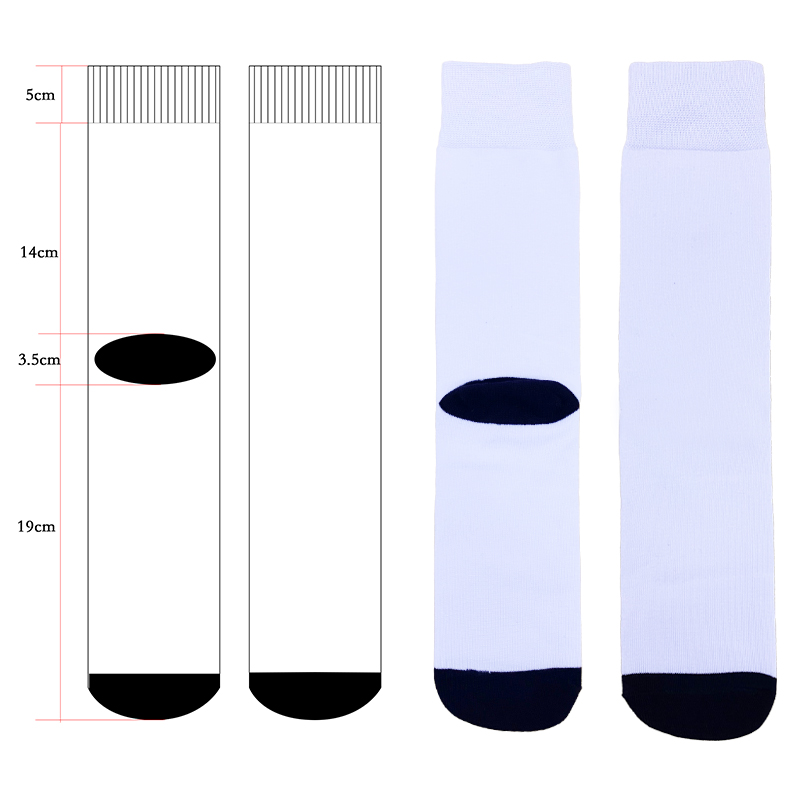

Product detail pictures:

Related Product Guide:

What Is UV Flat-Panel Printer?

Do You Know the Printing in China?

We know that we only thrive if we can easily guarantee our combined cost competiveness and high-quality advantageous at the same time for Factory For Dye Sublimation Printer 15Heads CO51915E to Albania Factories , The product will supply to all over the world, such as: Guatemala, Croatia, United States, We welcome you to visit our company & factory and our showroom displays various products that will meet your expectations. Meanwhile, it is convenient to visit our website. Our sales staff will try their best to provide you with the best services. If you need more information, please do not hesitate to contact us via E-mail, fax or telephone.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.