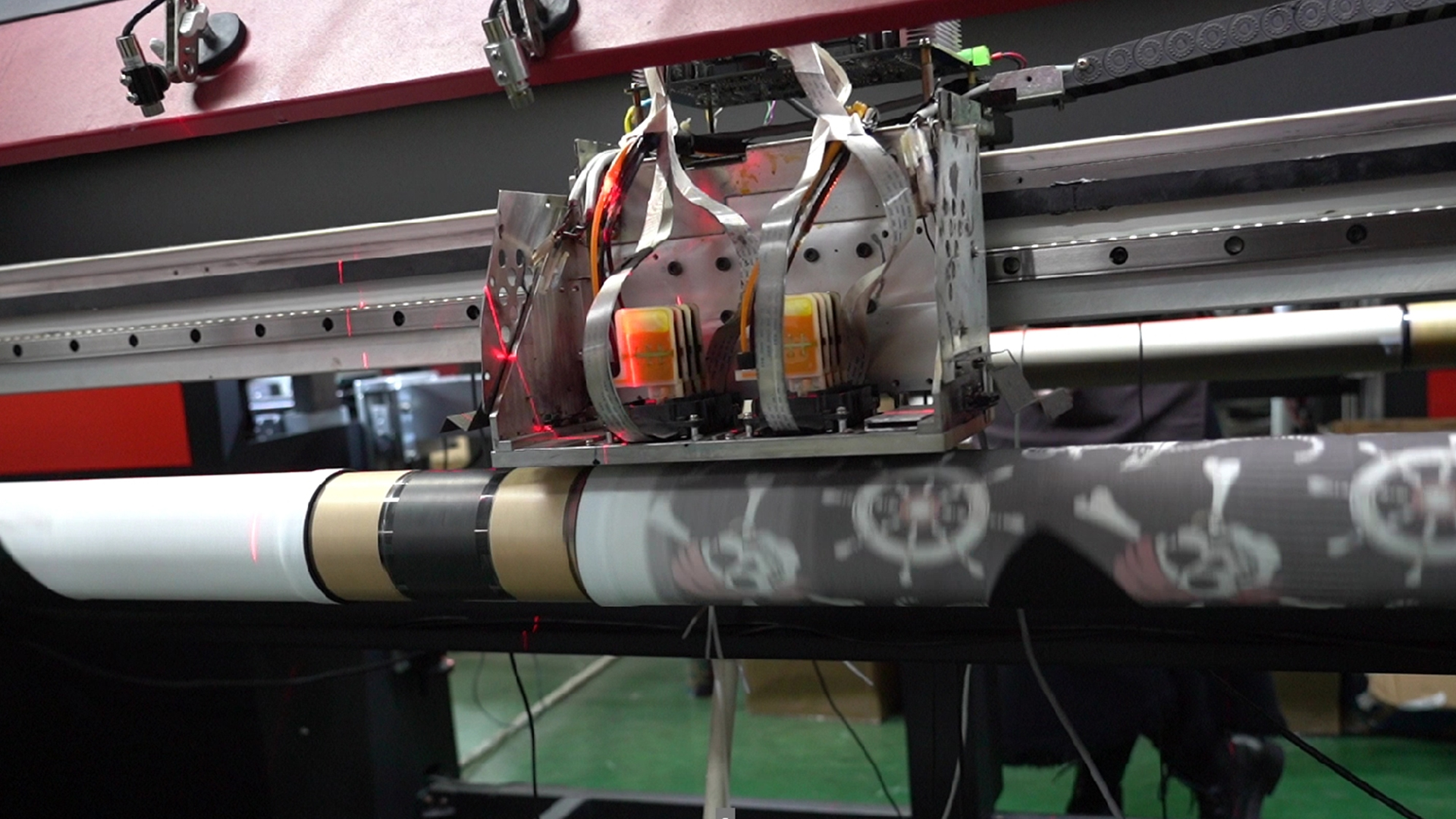

During the actual operation of digital socks printing, our workers often meet some printer heads problems. For example, while printing, you suddenly find that the color of the surface of the sock has changed, and one or several colors are missing,sometimes, no ink at all; or when printing, there are ink droplets on the surface of the sock; or the printed image is very clear and has double shadows. In response to these common problems, we need to cultivate workers' keen observation skills, stop printing in time to reduce losses, and have the ability to solve the above problems in a targeted manner.

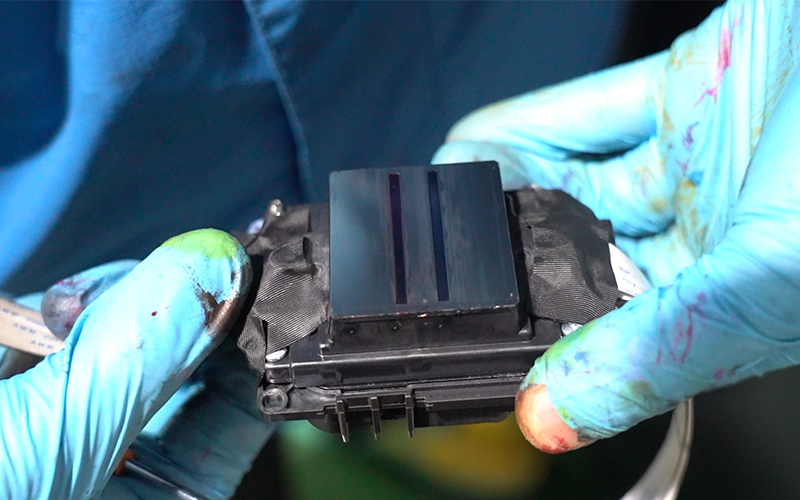

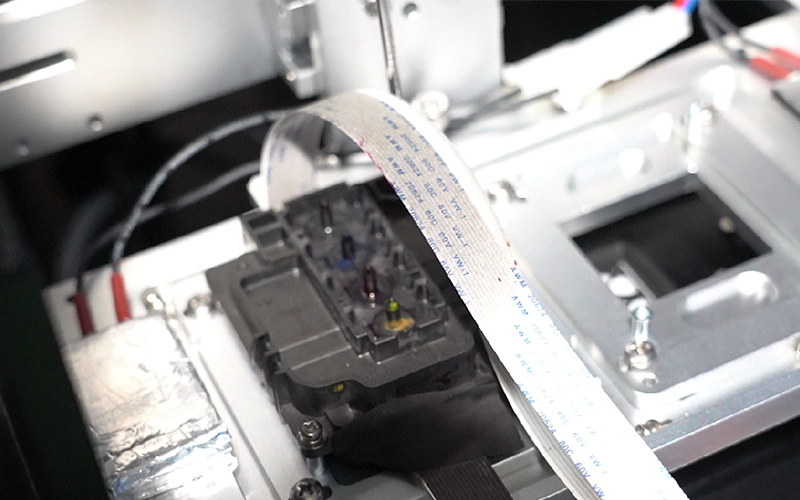

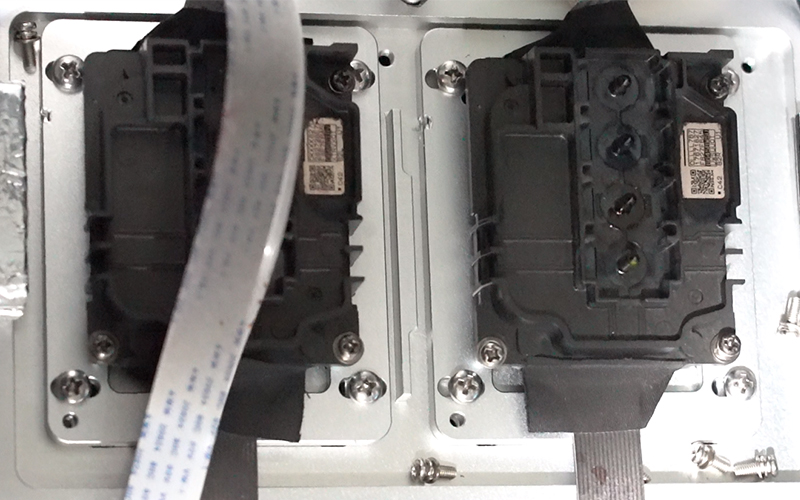

First, let's study the first problem - the print head does not produce ink or there is a problem with the ink production. Generally, we consider that the nozzle of the printer head is blocked. It should be cleaned repeatedly. Generally, after 3-4 times, test strips are printed and the nozzle can resume normal printing. If the problem still exists after repeated cleaning, there may be other problems. The first step is to replace the head cable. If it still doesn't work, consider the issue with the head board and replace it with a new one for testing. Doing this step can usually solve the problem, but if the problem still exists, it means that the printer head has been burned out or has been perforated, we can only replace the printer head.

The second problem is ink dripping. How to solve it? There are generally two reasons for this problem. One is that air enters the ink tube. If the liquid level of the secondary ink cartridge is too high or too low, air will enter the ink tube, requiring workers to adjust the level of ink in time. The second possibility is that the printer head has been used for too long. For example, in DX5, the head surface has a layer of film, which is severely worn during use. It can no longer hold the ink, and ink dripping will also occur. In this case, the printer head needs to be replaced.

The last situation is that the printing is not clear and there are ghost images. This is usually because the printer head is not calibrated or the physical position of the printer head is not adjusted properly. According to the printed test strip, set the most appropriate step and bidirectionality in the printing software. Adjust the physical position of the printer head. When installing the head, there should be no deviation in the position of the head. In addition, the height of the printer head from the surface of the socks should be adjusted according to the material thickness of the printed socks. If it is too low, it will easily rub the socks and stain them. If it is too high, the jetted ink will easily float, making the printed pattern unclear.

Hope the above 3 points can help you solve the printer head problem when you operate the socks printer.

Post time: Jan-23-2024